Abstract 摘要

Silica aerogel, as the earliest synthetic and commercially available one among all known aerogels, holds significant value in fields including thermal and acoustic insulation, optics, catalysis, sorption, etc. However, throughout its nearly century-long history, the influence of solvent used during synthesis on the properties of silica aerogels has been neglected, resulting in inaccurate and ambiguous performance evaluation. Herein, we have uncovered and systematically investigated the solvent-regulable interfacial groups that enable on-demand superhydrophobicity/superhydrophilicity of silica aerogels. During either sol-gel transition or solvent exchange process both required for aerogel synthesis, the alteration of solvent either from water to ethanol or vice versa leads to silica interfacial groups switch from superhydrophilic Si-OH to superhydrophobic Si-OEt or reversely due to reversible esterification, thus enabling on-demand superhydrophobic/superhydrophilic silica aerogels. It is worth noting that on-demand solvent-regulated hydrophilicity/hydrophobicity holds true regardless of used silica precursors (the mixture of trimethoxymethylsilane (MTMS)/tetramethoxysilane (TMOS), MTMS/tetraethyl orthosilicate (TEOS), or sodium methicosilicate (SMS)/TMOS), thereby indicating its universality, which wakes up considerable attention for producers involved in silica aerogels. Additionally, the discovery also provides a green, economical, and efficient way to achieve silica aerogels with on-demand hydrophilic/hydrophobic performance for specific sorption, etc.

作为所有已知气凝胶中最早合成和商业化的气凝胶,二氧化硅气凝胶在热学和声学绝缘、光学、催化、吸附等领域具有重要意义。然而,在其近一个世纪的历史中,合成过程中所用溶剂对二氧化硅气凝胶性能的影响一直被忽视,导致性能评估不准确且模糊不清。在此,我们揭示并系统研究了可通过溶剂调节的界面基团,使其能够实现按需的超疏水/超亲水二氧化硅气凝胶。无论是溶胶-凝胶转变过程还是气凝胶合成所需的溶剂交换过程,溶剂从水到乙醇的改变,或反之,都会导致二氧化硅界面基团从超亲水的 Si-OH 转变为超疏水的 Si-OEt,或反之,由于可逆酯化作用,从而实现按需的超疏水/超亲水二氧化硅气凝胶。 值得注意的是,按需溶剂调节亲水性和疏水性与所使用的硅氧烷前驱体无关(无论是三甲氧基甲硅烷(MTMS)/四甲氧基硅烷(TMOS)的混合物、MTMS/四乙氧基硅烷(TEOS)或四甲基甲硅酸钠(SMS)/TMOS),这表明其具有普适性,引起了涉及硅气凝胶生产的各方的关注。此外,这一发现还提供了一种绿色、经济且高效的方法,以实现具有按需亲水性和疏水性的硅气凝胶,用于特定的吸附等应用。

Similar content being viewed by others

其他用户正在查看相似内容

Introduction 简介

Aerogels are a vital kind of mesoporous nanomaterials, one of the ten emerging materials that will change the world, listed in Science1. Since first appearance of silica aerogels in 1931, a wide range of aerogels have been explored and extensively applied2,3,4,5,6,7. Among these different varieties, silica aerogels, being the earliest developed and extensively investigated, have undergone systematic exploration and rapid commercialization8. In academic aspect, silica aerogels possess distinctive characteristics such as high porosity, large specific surface area, low thermal conductivity, adjustable reflectivity, and scattering rate, as well as a low sound velocity due to their controllability in terms of building block size, pore structure, and three-dimensional (3D) branched network. In the commercial aspect, the unique properties of silica aerogels enable their wide application in environmental restoration9, thermal insulation10, optics11, and acoustics12. Silica aerogel products, such as monolith13, granule14, powder15, blanket16, and coating17, are extensively utilized in the aerospace industry18,19 as well as in manufacturing sectors20 and buildings21,22. These diverse applications establish the crucial role of silica aerogels in high-tech fields and economic development.

气凝胶是一种重要的介孔纳米材料,是《科学》杂志评选的未来将改变世界的十大新兴材料之一 1 。自 1931 年首次出现硅气凝胶以来,各种各样的气凝胶已被探索并广泛应用于多个领域 2,3,4,5,6,7 。在这众多品种中,硅气凝胶作为最早开发和研究最广泛的类型,已经经历了系统的探索和快速的商业化 8 。在学术方面,硅气凝胶具有高孔隙率、大比表面积、低热导率、可调反射率和散射率等特点,由于其在构建块尺寸、孔结构和三维(3D)分枝网络方面的可控性,使其具有独特的特性。在商业方面,硅气凝胶的独特性质使其在环境修复 9 、隔热 10 、光学 11 和声学 12 等领域有着广泛的应用。 硅气凝胶产品,如整体块体 13 、颗粒 14 、粉末 15 、毯状 16 和涂层 17 ,广泛应用于航空航天工业 18,19 、制造业 20 以及建筑领域 21,22 。这些多样的应用确立了硅气凝胶在高科技领域和经济发展中的关键作用。

Conventional synthetic routes on silica aerogels are based on the sol-gel transition of their precursors and gel aging in mother liquor, followed by solvent exchange and supercritical (Sc) drying or ambient pressure drying in sequence. The general sol-gel transition of silica precursors can be classified into one-step and two-step strategies. The one-step strategy involves direct hydrolysis and condensation in an acidic or basic solution, while the two-step strategy entails hydrolysis of silica precursors in an acidic solution followed by sequential condensation in an alkaline solution8. Up to now, most efforts are concentrated on exploring suitable reactants (such as silica precursors23, catalyst24, et al.) during the sol-gel process to tune the aerogel structures including building block sizes, pore geometry, and 3D networks to satisfy requirements for specific application scenarios25. Solvent, serving as reaction and drying media, plays crucial roles in the preparation of silica aerogels26. Various solvent treatments in sol-gel transition, solvent exchange, and Sc drying are required during the preparation of silica aerogels. For instance, a sequential treatment involving water and alcohol is commonly employed to effectively eliminate impurities such as inorganic salts27. It is generally believed that under mild solvent (water, ethanol) conditions, the chemical and physical properties of silica aerogels are stable. Only under harsh conditions (high temperature, high pressure, strong catalyst, etc.), the properties of silica aerogels will change greatly. For example, researchers have discovered that under harsh Sc conditions (240–245 °C), or strong acid-base catalysis, the silicon hydroxyl groups can be esterified with alcohols28,29,30,31, so as to achieve hydrophobic silica aerogels. However, despite its nearly century-long history, Nobody has reported that water/alcohol in the mild solvent process could lead to dramatic changes in the properties of silica aerogels, leading to inaccurate and ambiguous performance assessments of them.

传统合成二氧化硅气凝胶的方法基于前驱体的溶胶-凝胶转变及其在母液中的凝胶老化,随后进行溶剂交换和超临界(Sc)干燥或常压干燥。溶胶-凝胶转变的一般策略可以分为一步法和两步法。一步法涉及直接在酸性或碱性溶液中进行水解和缩合,而两步法则是在酸性溶液中水解二氧化硅前驱体,然后在碱性溶液中进行顺序缩合 8 。迄今为止,大多数努力集中在溶胶-凝胶过程中选择合适的反应物(如二氧化硅前驱体 23 、催化剂 24 等)以调控行结构,包括构建块尺寸、孔几何形状和三维网络,以满足特定应用场景的要求 25 。溶剂作为反应和干燥介质,在制备二氧化硅气凝胶过程中起着关键作用 26 。在制备二氧化硅气凝胶的过程中,需要在溶胶-凝胶转变、溶剂交换和超临界干燥过程中进行各种溶剂处理。 例如,通常采用依次用水和酒精处理的方法来有效去除杂质,如无机盐 27 。一般认为,在温和溶剂(水、乙醇)条件下,二氧化硅气凝胶的化学和物理性质是稳定的。只有在苛刻条件下(高温、高压、强催化剂等),二氧化硅气凝胶的性质才会发生巨大变化。例如,研究人员发现,在苛刻的 Sc 条件下(240-245℃)或强酸碱催化下,硅羟基可以与醇酯化 28,29,30,31 ,从而得到疏水性二氧化硅气凝胶。然而,尽管这一领域已有近一个世纪的历史,至今没有人报告过在温和溶剂处理过程中水/酒精会导致二氧化硅气凝胶性质发生剧烈变化,从而导致对其性能评估的不准确和模糊性。

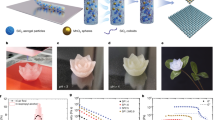

In this work, we comprehensively and systematically studied the solvent-regulated hydrophilic-hydrophobic interfacial group transitions during reaction and solvent exchange processes, and consequent fabrication of on-demand superhydrophobic (with water contact angle ≥150° as well as water sliding angle ≤10°)/superhydrophilic silica aerogels using a mixture of MTMS and TMOS as silica precursors (Fig. 1). During synthesis, hot water, and ethanol were employed as the reaction or exchange solvents to investigate the impact of mild solvents on the surface attribute of aerogel. The hydrophilicity/hydrophobicity of aerogel depends on the choice of hot water/ethanol used for the solvent treatment of the wet gel before Sc CO2 drying. The utilization of hot water results in the formation of wet hydrogel and subsequent superhydrophilic aerogel (SL-A) after Sc CO2 drying, while employing hot ethanol leads to the production of wet organogel and subsequent superhydrophobic aerogel (SB-A) after Sc CO2 drying. To distinguish them from regular wet gels, we here define wet hydrogel as SL-A precursors, and organogels as SB-A precursors. Therefore, the repetitive hot water/ethanol switching during the solvent exchange of the wet gel facilitates multiple switchable transitions between SL-A and SB-A precursors, thereby enabling on-demand SL and SB-As. The mechanism study indicates that such switchable SL-A and SB-A precursors are due to reversible esterification between Si-OH and ethanol. It is worth noting that this significant finding holds true for a wide range of silica precursors (the mixture of MTMS/TMOS, MTMS/TEOS, and SMS/TMOS), thereby indicating its universality in the preparation of silica aerogels. Additionally, the discovery also provides a green, economical, and efficient way to achieve on-demand SL/SB-As.

在本工作中,我们全面系统地研究了反应和溶剂交换过程中 MTMS 和 TMOS 混合物作为硅溶胶前驱体时溶剂调控的亲水-疏水界面基团转变,并据此合成了按需制备超疏水(水接触角≥150°,水滑动角≤10°)/超亲水硅气凝胶(图 1)。在合成过程中,使用热水和乙醇作为反应或交换溶剂,以研究温和溶剂对气凝胶表面属性的影响。气凝胶的亲水性/疏水性取决于在 Sc CO 2 干燥前使用热水/乙醇处理湿凝胶的选择。使用热水会导致湿凝胶形成,随后在 Sc CO 2 干燥后形成超亲水气凝胶(SL-A),而使用热水合乙醇则会导致湿有机凝胶形成,随后在 Sc CO 2 干燥后形成超疏水气凝胶(SB-A)。为了与常规湿凝胶区分开来,我们这里将湿凝胶定义为 SL-A 的前驱体,将有机凝胶定义为 SB-A 的前驱体。 因此,在湿凝胶溶剂交换过程中重复进行热水/乙醇切换,使得 SL-A 和 SB-A 前驱体之间可以实现多次可逆转换,从而实现按需制备 SL 和 SB-As。机制研究表明,这种可逆的 SL-A 和 SB-A 前驱体转换是由于 Si-OH 与乙醇之间的可逆酯化反应。值得注意的是,这一重要发现适用于多种硅溶胶(MTMS/TMOS 混合物、MTMS/TEOS 混合物和 SMS/TMOS 混合物),表明其在制备硅气凝胶中的普适性。此外,这一发现还提供了一种绿色、经济且高效的按需制备 SL/SB-As 的方法。

图 1:传统路线与我们路线的比较。

Schematic illustration of solvent-regulated switchable superhydrophobic–hydrophilic silica aerogels precursor transitions and synthesis of on-demand superhydrophobic/superhydrophilic aerogels reported in our study vs. synthesis of traditional silica aerogels without SB-A/SL-A precursor transitions. MTMS trimethoxymethylsilane, TMOS tetramethoxysilane, EtOH ethanol, SB-A superhydrophobic aerogel, SL-A superhydrophilic aerogel, Sc CO2 supercritical CO2.

溶剂调节可切换超疏水-亲水硅气凝胶前驱体转变示意图,以及在本研究中报道的按需超疏水/亲水气凝胶合成过程与传统硅气凝胶合成过程的对比。MTMS 三甲氧基甲硅烷,TMOS 四甲氧基硅烷,EtOH 乙醇,SB-A 超疏水气凝胶,SL-A 超亲水气凝胶,Sc CO 2 超临界 CO 2 。

Results 结果

Switchable SL-A/SB-A precursor transitions and on-demand aerogel superhydrophobicity/superhydrophilicity

可切换的 SL-A/SB-A 前驱体转变和按需气凝胶超疏水/超亲水性

The fabrication of silica aerogels includes three steps: sol-gel transition of silica precursors and aging, solvent exchange, and Sc CO2 dry. The three-dimensional porous skeleton formed via the sol-gel process can be preserved during the Sc drying process, thereby ensuring the successful formation of aerogels. For instance, here, the sol-gel transition and aging were performed with MTMS and TMOS as silica co-precursors, via hydrolyzation in hydrochloric acid at room termperature and condensation in ammonia aqueous and aging in mother liquor at 80 °C for 48 h. During solvent exchange, water, and ethanol were chosen as common solvents respectively depending on specific occasions, and sometimes, heating is necessary to accelerate the mass transfer rate. Two routes were designed using ethanol (Fig. 2a) and water (Fig. 3a) as reaction solvents to study the solvent effect during sol-gel transition and aging process. Likewise, hot ethanol and hot water were repeatedly switched in the solvent exchange progress to study the effect of solvent in this progress.

气凝胶的制备包括三个步骤:硅前驱体的溶胶-凝胶转变和老化、溶剂交换和干燥。通过溶胶-凝胶过程形成的三维多孔骨架可以在干燥过程中保留,从而确保气凝胶的成功形成。例如,这里使用 MTMS 和 TMOS 作为硅共前驱体,在室温下的盐酸中水解,在氨水溶液中进行缩合,并在母液中于 80 °C 下老化 48 小时进行溶胶-凝胶转变和老化。在溶剂交换过程中,根据具体情况分别选择水和乙醇作为溶剂,有时需要加热以加快质量传递速率。使用乙醇(图 2a)和水(图 3a)作为反应溶剂,设计了两条路线来研究溶剂效应在溶胶-凝胶转变和老化过程中的影响。同样,在溶剂交换过程中,反复使用热乙醇和热水来研究溶剂在此过程中的影响。

图 2:可切换的 SL-A/SB-A 前驱体及其相应的超疏水/超亲水硅气凝胶转变。

SB-A superhydrophobic aerogel, SL-A superhydrophilic aerogel. a Synthesis route of on-demand superhydrophilic/superhydrophobic silica aerogels with switchable SL-A/SB-A precursor transition by using ethanol as reaction solvent. MTMS trimethoxymethylsilane; TMOS tetramethoxysilane, EtOH ethanol, Sc CO2 supercritical CO2. b Photographs of silica aerogels (b1) and water contact angle on superhydrophobic silica aerogels (b2) and droplets with diverse color standing on silica aerogels (b3). Scale bar: b1 and b3: 1 cm; b2: 500 μm. c Water contact angles of silica aerogels from SB-A precursor after hot water treatment for different times. Scale bar: 500 μm. Error bar: <6.0°. d Water contact angles of silica aerogels from SL-A precursor after hot ethanol treatment for different times. Scale bar: 500 μm. Error bar: <4.5°. e Water contact angles of silica aerogels from cyclic SL-A/SB-A precursor transitions by treating wet gels alternately with hot water/ethanol. Error bar: <2.6°. f Water contact angles of silica aerogels with diverse M/T molar ratios from initial SB-A precursors (left) and water-induced SL-A precursors (right). M/T: MTMS: TMOS. g SEM image of silica aerogel from initial SB-A precursor. Scale bar: 500 nm. h Illustration of Cassie state to Wenzel state transition of silica aerogel from the initial SB-A precursor to the water induced SL-A precursor. Source data are provided as a Source Data file.

SB-超疏水气凝胶,SL-超亲水气凝胶。a 通过使用乙醇作为反应溶剂,从可切换 SL-A/SB-A 前驱体实现按需超亲水/超疏水二氧化硅气凝胶的合成路线。MTMS 三甲氧基甲硅烷;TMOS 四甲氧基硅烷;EtOH 乙醇;Sc CO 2 超临界 CO 2 。b 二氧化硅气凝胶的照片(b 1 )以及超疏水二氧化硅气凝胶上的水接触角(b 2 )和多种颜色的液滴在二氧化硅气凝胶上站立的照片(b 3 )。刻度尺:b 1 和 b 3 :1 cm;b 2 :500 μm。c 经不同时间热水处理后,从 SB-A 前驱体得到的二氧化硅气凝胶的水接触角。刻度尺:500 μm。误差条:<6.0°。d 经不同时间热乙醇处理后,从 SL-A 前驱体得到的二氧化硅气凝胶的水接触角。刻度尺:500 μm。误差条:<4.5°。e 通过交替用热水/乙醇处理湿凝胶实现循环 SL-A/SB-A 前驱体转换后,得到的二氧化硅气凝胶的水接触角。误差条:<2.6°。f 不同 M/T 摩尔比的二氧化硅气凝胶,从初始 SB-A 前驱体(左)和水诱导的 SL-A 前驱体(右)得到。M/T:MTMS: TMOS。 g 从初始 SB-A 前驱体制备的硅气凝胶的扫描电子显微镜图像。比例尺:500 nm。h 从初始 SB-A 前驱体到水诱导的 SL-A 前驱体,硅气凝胶从卡西实验态转变为温泽尔态的示意图。源数据文件提供于源数据文件中。

图 3:可切换的 SL-A/SB-A 前驱体及其对应的超疏水/超亲水硅气凝胶转变。

SB-A superhydrophobic aerogel, SL-A superhydrophilic aerogel. a Synthetic route of on-demand superhydrophilic/superhydrophobic silica aerogels with switchable SL-A/SB-A precursor transition by using water as a reaction solvent. MTMS trimethoxymethylsilane, TMOS tetramethoxysilane, EtOH ethanol, Sc CO2 supercritical CO2. b Photographs of silica aerogels (b1) and water contact angles on superhydrophilic silica aerogels initially (b2) and later (b3). Scale bar: b1: 1 cm; b2 and b3: 500 μm. c Water contact angles of silica aerogels from SL-A precursor after hot ethanol treatment for different times. Scale bar: 500 μm. Error bar: <7.9°. d Water contact angles of silica aerogels from SB-A precursor after hot water treatment for different times. Scale bar: 500 μm. Error bar: <7.4°. e Water contact angles of silica aerogels from cyclic SL-A/SB-A precursor transitions by treating wet gels alternately with hot ethanol/water. Error bar: <2.5°. f Water contact angles of silica aerogels with diverse M/T molar ratios from initial SL-A precursors (left) and ethanol-induced SB-A precursors (right). M/T: MTMS: TMOS. g SEM image of silica aerogels from initial SB-A precursor. Scale bar: 500 nm. h Illustration of Wenzel state to Cassie state transition of silica aerogel from initial SL-A precursor to ethanol-induced SL-A precursor. Source data are provided as a Source Data file.

SB-超疏水气凝胶,SL-超亲水气凝胶。a 通过使用水作为反应溶剂,实现超亲水/超疏水二氧化硅气凝胶的可需求切换合成路线,由可切换的 SL-A/SB-A 前驱体过渡。MTMS 三甲氧基甲硅烷,TMOS 四甲氧基硅烷,EtOH 乙醇,Sc CO 2 超临界 CO 2 。b 超亲水二氧化硅气凝胶的照片(b 1 )以及初始(b 2 )和后来(b 3 )的水接触角。刻度尺:b 1 :1 cm;b 2 和 b 3 :500 μm。c 经不同时间热乙醇处理后,从 SL-A 前驱体得到的二氧化硅气凝胶的水接触角。刻度尺:500 μm。误差条:<7.9°。d 经不同时间热水处理后,从 SB-A 前驱体得到的二氧化硅气凝胶的水接触角。刻度尺:500 μm。误差条:<7.4°。e 通过交替用热乙醇/水处理湿凝胶,实现循环 SL-A/SB-A 前驱体过渡后,二氧化硅气凝胶的水接触角。误差条:<2.5°。f 不同 M/T 摩尔比的二氧化硅气凝胶,从初始 SL-A 前驱体(左)和乙醇诱导的 SB-A 前驱体(右)得到。M/T:MTMS: TMOS。 g 从初始 SB-A 前驱体制备的硅气凝胶的扫描电子显微镜图像。比例尺:500 nm。h 从初始 SL-A 前驱体到乙醇诱导的 SL-A 前驱体的硅气凝胶的 Wenzel 状态到 Cassie 状态转变示意图。源数据文件提供源数据。

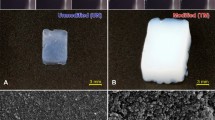

In synthetic route 1, alcohol was commonly used in the sol-gel process for organosiloxane precursors (Fig. 2a). The structures and surface attributes of aerogel fabricated with ethanol as a sol-gel solvent were first studied in detail. As illustrated in Fig. 2a, under acid-base catalysis, the co-precursors of MTMS and TMOS undergo hydrolysis and condensation in sequence to form SB-A precursors. Following Sc CO2 drying, translucent superhydrophobic silica aerogels were obtained with density of 0.127 ± 0.004 g/cm3 (Fig. 2b). Such aerogel networks were composed of silica primary particles with a radius of about 3.30 ± 0.61 nm with large specific surface area and small pore widths (Supplementary Fig. 1). For example, the specific surface area is 1047 m2/g for samples obtained by co-precursors with a molar ratio of MTMS/TMOS (M/T) 7:3, 1036 m2/g for that of M/T 6:4, 759 m2/g for that of M/T 5:5 and 803 m2/g for that of M/T 4:6, respectively. Also, the adsorption average pore widths of such silica aerogels are 7.3 nm for that of M/T 7:3, 9.3 nm for that of M/T 6:4, 10.6 nm for that of M/T 5:5 and 11.3 nm for that of M/T 4:6, respectively, similar to or higher than reported data32. Superhydrophobicity of aerogel was reflected directly by water contact angle as high as 150.6° ± 0.2° (Fig. 2b2), with water sliding angle as low as 2.9° ± 0.8° and multiple water droplet resilience (Supplementary Figs. 2 and 3). Hence, water droplets dyed with purple, green or white pigments can never infiltrate into such superhydrophobic silica aerogels (Fig. 2b3 and Supplementary Fig. 4). However, during the solvent exchange process, if ethanol in the SB-A precursor was completely substituted with water and holding at 80 °C for a specific duration, followed by Sc CO2 drying, gradual formation of superhydrophilic silica aerogel can be achieved. The water contact angles of obtained silica aerogels are negatively correlated with the hot water treatment time for SB-A precursors. As illustrated in Fig. 2c, with an increase of water treatment time for SB-A precursor, water contact angles of the obtained silica aerogels decrease gradually, reducing from 149.4° to 110.1°, 74.4°, 67.2° and even 0° for samples prepared with the molar ratio of M/T 7:3 after 72 h, which displays great potential in on-demand surface attribute regulation from SB-A to SL-A precursors. Additionally, the SB-A precursors and corresponding superhydrophobic silica aerogels can be reobtained by resubstituting water in SL-A precursor with ethanol, holding it at 80 °C for a specific duration, and Sc CO2 drying. During the transition from SL-A to SB-A precursors, Water contact angle of relative aerogel increases gradually from 0°, 102.5°, 120.7°, 135.1° to 150.4° (Fig. 2d). Such water-induced SL-A precursors and the ethanol-induced recuperative SB-A precursors are switchable and can be fully cycled for at least ten loops(Fig. 2e). These SB-As exhibit consistent static water contact angles of 150.8° ± 0.9o and water sliding angles of 5.8° ± 1.4o, and SL-A have constant water contact angles of 0°, indicating the stability and reversibility of these cyclic processes (Supplementary Fig. 5a). Beyond the molar ratio of M/T of 7:3, such water-induced transition from SB-A to SL-A precursors and formation of SL-A were applicable to other ratios of M/T of 5:5, 6:4, and 4:6, indicating the universality of the phenomenon (Fig. 2f and Supplementary Fig. 5b).

在合成路线 1 中,醇通常被用作有机硅氧烷前驱体溶胶-凝胶过程中的溶剂(图 2a)。首先详细研究了以乙醇作为溶胶-凝胶溶剂制备的气凝胶的结构和表面属性。如图 2a 所示,在酸碱催化下,MTMS 和 TMOS 的共前驱体依次经历水解和缩合反应形成 SB-A 前驱体。经过 Sc CO 2 干燥后,获得了密度为 0.127 ± 0.004 g/cm³的透明超疏水二氧化硅气凝胶(图 2b)。这种气凝胶网络由平均粒径约为 3.30 ± 0.61 nm 的二氧化硅初级粒子组成,具有较大的比表面积和较小的孔径(补充图 1)。例如,当 MTMS/TMOS 摩尔比(M/T)为 7:3 时,样品的比表面积为 1047 m²/g;M/T 为 6:4 时,比表面积为 1036 m²/g;M/T 为 5:5 时,比表面积为 759 m²/g;M/T 为 4:6 时,比表面积为 803 m²/g。 此外,这类硅气凝胶的吸附平均孔径分别为:M/T 7:3 为 7.3 nm,M/T 6:4 为 9.3 nm,M/T 5:5 为 10.6 nm,M/T 4:6 为 11.3 nm,与已报道的数据相似或更高 32 。气凝胶的超疏水性直接体现在水接触角高达 150.6°±0.2°(图 2b 2 ),滑动角低至 2.9°±0.8°,以及多个水滴的反弹性(补充图 2 和 3)。因此,染成紫色、绿色或白色颜料的水滴永远无法渗透到这种超疏水硅气凝胶中(图 2b 3 和补充图 4)。然而,在溶剂交换过程中,如果将 SB-A 前驱体中的乙醇完全替换为水,并在 80°C 下保持特定时间,随后进行 Sc CO 2 干燥,可以逐渐形成超亲水硅气凝胶。所得硅气凝胶的水接触角与 SB-A 前驱体的热水处理时间呈负相关。如图所示 2 2c,随着 SB-A 前驱体水处理时间的增加,所得硅气凝胶的水接触角逐渐减小,从 149.4°降至 110.1°、74.4°、67.2°,甚至在 72 小时后降至 0°,这显示了从 SB-A 到 SL-A 前驱体中按需调节表面属性的巨大潜力。此外,通过用乙醇替换 SL-A 前驱体中的水,在 80°C 下保持特定时间并进行 Sc CO 2干燥,可以重新获得 SB-A 前驱体和相应的超疏水硅气凝胶。在从 SL-A 到 SB-A 前驱体的过渡过程中,相对气凝胶的水接触角逐渐从 0°、102.5°、120.7°、135.1°升至 150.4°(图 2d)。这种水诱导的 SL-A 前驱体和乙醇诱导的可恢复 SB-A 前驱体是可切换的,并且可以至少循环十次(图 2e)。这些 SB-A 表现出一致的静态水接触角 150.8°±0.9 o 和水滑动角 5.8°±1.4 o ,而 SL-A 则具有恒定的水接触角 0°,表明这些循环过程的稳定性和可逆性(补充图 5a)。 在 M/T 摩尔比为 7:3 以上时,这种水诱导的从 SB-A 到 SL-A 前驱体的转变以及 SL-A 的形成对其他 M/T 比例如 5:5、6:4 和 4:6 也同样适用,表明该现象的普遍性(图 2f 和补充图 5b)。

The inner network structures of superhydrophobic silica aerogel from initial SB-A precursor and SL-A from the water-induced SL-A precursor were tracked for better understanding the wetting behavior of these aerogels. From the scanning electron microscopy (SEM) images and 3D confocal microscope images, it is evident that all aerogel surfaces exhibit rough morphologies (Fig. 2g and Supplementary Figs. 6–8). To gain deeper insights into the wetting behavior transition from superhydrophobic to SL-A, the Cassie-Wenzel wetting model was employed. For SB-A with a water contact angle of 150° and a water sliding angle of 3.66°, water droplets did not infiltrate into the aerogel pores but instead rolled off rapidly down an incline, akin to the lotus leaf effect. This behavior can be effectively explained by the Cassie model. As the water treatment time increased, the water contact angle decreased slightly to 149° while the water sliding angle gradually increased to 15.38°. With further prolonged water treatment, the water contact angle continued to decrease to 127°, and droplets no longer rolled off even when the aerogel was inverted 180°, indicating a high adhesion state similar to the petal effect. According to literature, possible wetting states at this stage include the Wenzel state with strong pinning sites33,34,35. Upon extended water treatment, SL-A with a water contact angle of 0° was obtained, where water droplets fully infiltrated the aerogel pores (Supplementary Fig. 9). Consequently, its wetting behavior can be well described by the Cassie-Wenzel model. The results demonstrate that as water treatment time increases, the wetting state of water droplets on the aerogel surface transitions from the Cassie state to the Wenzel state (Fig. 2h).

从初始 SB-A 前驱体和水诱导的 SL-A 前驱体制备的超疏水二氧化硅气凝胶的内部网络结构被追踪,以便更好地理解这些气凝胶的润湿行为。从扫描电子显微镜(SEM)图像和三维共聚焦显微镜图像可以看出,所有气凝胶表面都表现出粗糙的形态(图 2g 和补充图 6-8)。为了更深入地了解从超疏水到 SL-A 的润湿行为转变,采用了 Cassie-Wenzel 润湿模型。对于接触角为 150°、滑动角为 3.66°的 SB-A,水滴并未渗透到气凝胶孔隙中,而是迅速沿斜面滚动,类似于莲花叶效应。这种行为可以用 Cassie 模型有效解释。 随着水处理时间的增加,水接触角略微下降至 149°,而水滑动角逐渐增加至 15.38°。进一步延长水处理时间后,水接触角继续下降至 127°,即使将气凝胶倒置 180°,水滴也不再滚动,表明其处于类似花瓣效应的高粘附状态。根据文献,此时可能的润湿状态包括具有强烈粘附位点的 Wenzel 状态 33,34,35 。经过更长时间的水处理后,SL-A 的水接触角降至 0°,水滴完全浸入气凝胶孔隙中(补充图 9)。因此,其润湿行为可以用 Cassie-Wenzel 模型很好地描述。结果表明,随着水处理时间的增加,气凝胶表面水滴的润湿状态从 Cassie 状态过渡到 Wenzel 状态(图 2h)。

Water was another common solvent used in sol-gel process for silica precursors in synthetic route 2 (Fig. 3a). To further validate feasibility of solvent-regulable SL-A/SB-A precursor transitions and on-demand superhydrophobicity/superhydrophilicity controlling, we synthesized silica aerogels directly using water as solvent at sol-gel transition step. As illustrated in Fig. 3a, in water, the above-mentioned same precursor mixture of MTMS and TMOS first hydrolyze in dilute hydrochloric acid and then condense in ammonium hydroxide to form SL-A precursor. Followed with Sc CO2 drying, superhydrophilic silica aerogels with density among (0.113 ± 0.004 g/cm3) are obtained. It is worth noting that at same conditions with route 1 in Fig. 2a, here, only changing the solvent in the so-gel transition process from ethanol to water leaded to the formation of superhydrophilic silica aerogels. Such silica aerogels are translucent (Fig. 3b) and water droplet will be immediately adsorbed once contact with each other (Fig. 3b2, b3). Such aerogel networks were composed of silica primary particles with a radius of about 4.11 nm with specific surface area of 472 m2/g for silica aerogels prepared by co-precursors with molar ratio of M/T 7:3, 579 m2/g for that of M/T 6:4, 547 m2/g for that of M/T 5:5 and 567 m2/g for that of M/T 4:6, respectively. Also, their corresponding adsorption average pore width is 8.6 nm, 9.2 nm, 12.3 nm, and 8.5 nm respectively (Supplementary Fig. 10). Similar to the above phenomenon, if the water in SL-A precursors was substituted with ethanol under heating, SB-A precursors come into being and superhydrophobic silica aerogels are produced after Sc CO2 drying. Under different treatment time in such process, water contact angles of the resulting silica aerogels change from 0° to 115.8°, 143.4°, 1501.2°, and 153.0° for M/T 7/3 silica aerogels (Fig. 3c). Also, superhydrophilic silica aerogel can be reobtained once ethanol in SB-A precursor was replaced with water during solvent exchange process, with water contact angles reducing from 148.8°, 131.3°, 112.6°, 83.7° and 0° for M/T 7/3 silica aerogels (Fig. 3d). Such ethanol-induced SB-A precursors and the water-induced recuperative SL-A precursors are switchable and can be fully cycled for at least ten loops (Fig. 3e) with water contact angle and sliding angle remain 151° ± 1° and 6.5° ± 1.9°, respectively (Supplementary Fig. 11a) and multiple water droplet resilience (Supplementary Figs. 2 and 3). Same trends also happen to silica aerogels obtained by other molar ratios of M/T 6:4, 5:5, and 4:6, respectively, indicating the universality of the phenomenon again (Fig. 3f and Supplementary Fig. 11b).

水是合成路线 2(图 3a)中用于硅前驱体溶胶-凝胶过程的另一种常见溶剂。为进一步验证溶剂可调节的 SL-A/SB-A 前驱体转变和按需控制超疏水/超亲水性的可行性,我们直接使用水作为溶剂在溶胶-凝胶转变步骤中合成了硅气凝胶。如图 3a 所示,在水中,上述 MTMS 和 TMOS 的相同前驱体混合物首先在稀盐酸中水解,然后在氨水中共缩聚形成 SL-A 前驱体。随后经过 Sc CO 2 干燥,得到密度在(0.113 ± 0.004 g/cm³)之间的超亲水硅气凝胶。值得注意的是,在图 2a 所示的相同条件下,这里仅通过将溶胶-凝胶转变过程中的溶剂从乙醇改为水,就形成了超亲水硅气凝胶。这种硅气凝胶是半透明的(图 3b),一旦水滴接触,就会立即被吸附(图 3b 2 ,b 3 )。 这些气凝胶网络由平均粒径约为 4.11 nm 的二氧化硅初级颗粒组成,比表面积分别为:使用摩尔比 M/T 7:3 的共前驱体制备的二氧化硅气凝胶为 472 m²/g,摩尔比 M/T 6:4 的为 579 m²/g,摩尔比 M/T 5:5 的为 547 m²/g,摩尔比 M/T 4:6 的为 567 m²/g(补充图 10)。相应地,它们的吸附平均孔径分别为 8.6 nm、9.2 nm、12.3 nm 和 8.5 nm。类似上述现象,如果将 SL-A 前驱体中的水在加热条件下替换为乙醇,则会生成 SB-A 前驱体,并在 Sc CO 2 干燥后产生超疏水二氧化硅气凝胶。在该过程中不同处理时间下,所得二氧化硅气凝胶的水接触角从 0°变化到 115.8°、143.4°、150.1°和 153.0°(图 3c)。同时,在溶剂交换过程中将 SB-A 前驱体中的乙醇替换为水,可以重新获得超亲水二氧化硅气凝胶,所得二氧化硅气凝胶的水接触角从 148.8°、131.3°、112.6°、83.7°和 0°(图 3d)变化。 这种由乙醇诱导的 SB-A 前驱体和由水诱导的恢复型 SL-A 前驱体是可以切换的,并且可以至少循环十轮(图 3e),接触角和滑动角分别保持在 151°±1°和 6.5°±1.9°(补充图 11a)以及多次水滴恢复性(补充图 2 和 3)。其他摩尔比 M/T 分别为 6:4、5:5 和 4:6 获得的二氧化硅气凝胶也表现出相同趋势,再次表明该现象的普遍性(图 3f 和补充图 11b)。

Similarly, the inner network structures of superhydrophilic silica aerogel from the initial SL-A precursor and SB-A from ethanol-induced SB-A precursor were tracked for a better understanding the wetting behaviors of these aerogels. From the SEM and 3D confocal microscope images, all aerogel surfaces exhibit rough morphologies (Fig. 3g and Supplementary Figs. 12–14). The wetting behaviors from superhydrophilic to SB-As were also investigated. For SL-A with a water contact angle of 0°, water droplets infiltrate into the aerogel pores. As the ethanol treatment time increased, the water contact angle gradually rose to 113°, and the droplets exhibited high adhesion, which can be accurately described by the Wenzel model. With further increases in ethanol treatment time, the water contact angle increased to 150°, and water droplets began to roll on an inclined surface of aerogel at a water sliding angle of 15.38°. Finally, the water contact angle reached 151° with a reduced water sliding angle of 3.57°, indicating a transition to the Cassie state (Supplementary Fig. 15). These results demonstrate that the wetting behavior evolves from the Wenzel to the Cassie state as the ethanol treatment time extends.

同样,从初始 SL-A 前驱体和乙醇诱导的 SB-A 前驱体制备的超亲水二氧化硅气凝胶的内部网络结构也得到了跟踪,以便更好地理解这些气凝胶的润湿行为。从 SEM 和三维共焦显微镜图像中可以看出,所有气凝胶表面都表现出粗糙的形态(图 3g 和补充图 12-14)。从超亲水到 SB-A 的润湿行为也进行了研究。对于水接触角为 0°的 SL-A,水滴能够渗透到气凝胶孔隙中。随着乙醇处理时间的增加,水接触角逐渐上升至 113°,并且水滴表现出较高的附着力,这可以用 Wenzel 模型准确描述。进一步增加乙醇处理时间后,水接触角上升至 150°,水滴开始在气凝胶倾斜表面上以 15.38°的滑动角滚动。最后,水接触角达到 151°,滑动角减小至 3.57°,表明气凝胶进入 Cassie 状态(补充图 15)。 这些结果表明,随着乙醇处理时间的延长,润湿行为从温泽状态转变为卡西叶状态。

Above all, solvent-regulable surface attribute change of silica aerogels was investigated by selecting different sol-gel routes and solvent exchange treatment. When using ethanol as sol-gel solvent, superhydrophobic silica aerogels were obtained. While, using water as sol-gel solvent, superhydrophilic silica aerogels were produced. Additionally, reversible transitions between SB-A precursor and SL-A precursor can be achieved by solvent exchange in ethanol and water respectively at 80 °C, resulting in on-demand superhydrophobic/superhydrophilic silica aerogels and tunable wetting behavior. In short, water induces the superhydrophilicity, and ethanol results in superhydrophobicity. All these confirm the feasibility of solvent-regulated switchable SB-A/SL-A precursor transitions and on-demand superhydrophobicity/superhydrophilicity of silica aerogels.

首先,通过选择不同的溶胶-凝胶路线和溶剂交换处理,研究了硅气凝胶的溶剂可调表面属性变化。使用乙醇作为溶胶溶剂时,获得了超疏水硅气凝胶;而使用水作为溶胶溶剂时,则获得了超亲水硅气凝胶。此外,通过在 80°C 下分别使用乙醇和水进行溶剂交换,可以实现 SB-A 前驱体和 SL-A 前驱体之间的可逆转换,从而获得按需超疏水/超亲水硅气凝胶和可调的润湿行为。简而言之,水诱导超亲水性,而乙醇则导致超疏水性。所有这些都证实了溶剂调节的可转换 SB-A/SL-A 前驱体转换和硅气凝胶的按需超疏水性/超亲水性的可行性。

Reversible SL-A/SB-A precursor transition mechanism

可逆的 SL-A/SB-A 前驱体转换机制

It is well established that the wettability of a substrate surface is primarily influenced by two factors: surface chemical composition and surface microstructure36. SEM and 3D confocal images revealed no significant differences in the micro- and nano-scale surface morphologies between superhydrophilic and superhydrophobic silica aerogels, both exhibiting similar roughness values and spherical secondary particles (Supplementary Figs. 6–7 and 12–14). Therefore, it is reasonable to infer that the superhydrophobic and superhydrophilic properties of silica aerogels are predominantly attributed to variations in their surface chemical composition. To further explore the mechanisms, we use attenuated total reflection infrared (ATR-IR) spectra and solid-state nuclear magnetic resonance (NMR) spectra to characterize the chemical structure changes of such silica aerogels (Fig. 4). Based on these data analyses, we deduce that esterification reaction and its inverse reaction play a crucial role in the switchable SB-A precursor and SL-A precursor transition (Fig. 4a). Firstly, in the normalized ATR-IR spectra by standardized signals of absorbance at 1275 cm−1 (vibration of Si-C groups)37, the intensity of absorbance at 1035 cm−1 (ascribing to stretching vibrations of Si-O and C-O groups) and absorbance at 2940 cm−1 (ascribing to symmetric stretching vibrations of C-H from -OCH2CH3 groups) and absorbance at 2980 cm−1 (ascribing to antisymmetric stretching vibrations of C-H from Si-CH3 or Si-OCH2CH3 groups)38,39, are comparatively weaker in superhydrophilic silica aerogels compared to their superhydrophobic counterparts (Fig. 4b). Simultaneously, the absorption bands at 3448 cm−1 and 1638 cm−1, associated with vibrations of O-H groups, exhibit stronger intensity in superhydrophilic silica aerogels than those superhydrophobic counterparts40. The results indicate an abundance of C-O and C-H bonds on hydrophobic silica aerogels and -OH groups on hydrophilic silica aerogels, aligning well with the aforementioned hydrophobic/hydrophilic properties. Based on this, one rational hypothesis was proposed that in ethanol, the formation of -OCH2CH3 bonds are induced by condensation reactions between -OH groups and ethanol, Conversely, in water, hydrolysis of Si-O-C chemical bonds leads to the regeneration of -OH.

已知基底表面的润湿性主要受两个因素影响:表面化学组成和表面微观结构。SEM 和三维共焦显微镜图像显示,超亲水和超疏水二氧化硅气凝胶在微米和纳米尺度上的表面形态没有显著差异,两者表现出相似的粗糙度值和球形次级颗粒(补充图 6-7 和 12-14)。因此,可以合理推断,二氧化硅气凝胶的超疏水和超亲水性质主要归因于其表面化学组成的差异。为了进一步探索其机制,我们使用衰减全反射红外光谱(ATR-IR)和固体核磁共振光谱(NMR)来表征这类二氧化硅气凝胶的化学结构变化(图 4)。基于这些数据分析,我们推断酯化反应及其逆反应在可切换的 SB-A 前驱体和 SL-A 前驱体转变中起着关键作用(图 4a)。 首先,在归一化的 ATR-IR 光谱中,通过标准化信号(Si-C 键的振动在 1275 cm⁻¹处的吸收强度) −1 、Si-O 和 C-O 键的拉伸振动(在 1035 cm⁻¹处的吸收强度) 37 、-OCH₃或-OCH₂CH₃基团的 C-H 对称拉伸振动(在 2940 cm⁻¹处的吸收强度) −1 以及 Si-CH₃或 Si-OCH₂CH₃基团的 C-H 反对称拉伸振动(在 2980 cm⁻¹处的吸收强度) −1 ,超疏水二氧化硅气凝胶的吸收强度相对较弱,而超亲水二氧化硅气凝胶的吸收强度较强(图 4b)。同时,与 O-H 键振动相关的吸收带(在 3448 cm⁻¹和 1638 cm⁻¹处) 2 在超亲水二氧化硅气凝胶中的强度比超疏水气凝胶更强 3 。这些结果表明,超疏水二氧化硅气凝胶上存在丰富的 C-O 和 C-H 键,而超亲水二氧化硅气凝胶上存在丰富的-OH 基团,这与上述的疏水性和亲水性特性一致。 基于此,提出一个合理的假设:在乙醇中,-OH 基团与乙醇之间的缩合反应诱导形成了-OCH 2 CH 3 键;相反,在水中,Si-O-C 化学键的水解导致-OH 的再生。

图 4:可切换 SL-A/SB-A 前驱体转变的机制研究

SB-A superhydrophobic aerogel, SL-A superhydrophilic aerogel. a Diagram illustration of solvent-regulable interfacial groups by reversible esterification reaction. b ATR-IR spectra, c 29Si CP MAS NMR spectra, and d 13C CP MAS NMR spectra of corresponding superhydrophobic/superhydrophilic silica aerogels (MTMS/TMOS 5:5) from SB-A/SL-A precursors. MTMS trimethoxymethylsilane, TMOS tetramethoxysilane. Qn denotes a tetrahedral Si with n bridging oxygens, Tn stands for a tetrahedral Si with 1C and n bridging oxygens. Source data are provided as a Source Data file.

SB-超疏水气凝胶,SL-超亲水气凝胶。a 通过可逆酯化反应调节界面基团的示意图。b ATR-IR 光谱,c 29 Si CP MAS NMR 光谱,d 13 C CP MAS NMR 光谱,分别对应于由 SB-A/SL-A 前驱体制备的超疏水/超亲水硅气凝胶(MTMS/TMOS 5:5)。MTMS 三甲氧基甲硅烷,TMOS 四甲氧基硅烷。Qn 表示具有 n 个配位氧的四面体硅,Tn 表示具有 1 个 C 和 n 个配位氧的四面体硅。源数据文件提供源数据。

To exactly characterize chemical structure of superhydrophilic and superhydrophobic silica aerogels, NMR spectrum was tested. From29Si cross-polarization magic angle spinning NMR spectrum in Fig. 4c, for superhydrophobic silica aerogels and superhydrophilic ones, the signals of Q4 (−112 ppm), Q3 (−100 ppm) and T3 (−65 ppm) and T2 (−58 ppm) display no distinct difference, where Qn denotes a tetrahedral Si with n bridging oxygens, Tn stands for a tetrahedral Si with 1C and n bridging oxygens41. This means that the switchable transition between superhydrophobic-superhydrophilic silica aerogel precursors does not change the Qn or Tn species, that is, the bridging Si-O-Si bands are stable during hydrolysis/alcoholysis and the esterification and hydrolysis reactions mainly occur on Si-OH and Si-O-CH2CH3 groups. Furthermore, the strong signals at chemical shifts of 12 ppm and 53 ppm in the 13C NMR spectra indicated the existence of -OCH2CH3 groups42 in superhydrophobic silica aerogels, while no signals were observed in superhydrophilic silica aerogels (Fig. 4d). This confirmed that there are more ethyl groups on the hydrophobic aerogels than hydrophilic aerogels.

为了精确表征超亲水和超疏水硅气凝胶的化学结构,进行了核磁共振(NMR)谱测试。从图 4c 中的 29 Si 交叉极化魔角旋转 NMR 谱图可以看出,对于超疏水硅气凝胶和超亲水硅气凝胶,Q 4 (-112 ppm)、Q 3 (-100 ppm)、T 3 (-65 ppm)和 T 2 (-58 ppm)的信号没有明显差异,其中 Qn 表示具有 n 个配位氧的四面体 Si,Tn 表示具有 1 个 C 和 n 个配位氧的四面体 Si 41 。这意味着超疏水-超亲水硅气凝胶前驱体之间的可切换转变并没有改变 Qn 或 Tn 物种,即在水解/醇解和酯化及水解反应过程中,配位 Si-O-Si 键是稳定的,主要的反应发生在 Si-OH 和 Si-O-CH 2 CH 3 基团上。此外, 13 C NMR 谱图中 12 ppm 和 53 ppm 的强信号表明超疏水硅气凝胶中存在-OCH 2 CH 3 基团,而在超亲水硅气凝胶中未观察到相应信号(图 4d)。 这证实了疏水气凝胶中的乙基基团含量高于亲水气凝胶。

All results affirm the mechanism that esterification between Si-OH and ethanol induced the generation of hydrophobic Si-OCH2CH3 groups in 80 °C ethanol during fabrication of superhydrophobic silica aerogels. Hydrolysis of Si-OCH2CH3 into Si-OH in 80 °C water leads to the increasing ratio of hydrophilic groups during fabrication of superhydrophilic silica aerogels. Besides, it should be noted that esterification and hydrolysis are necessary but not sufficient conditions for achieving reversible SL-A/SB-A precursor transitions. M/T molar ratio and reaction time are two other important factors. When the M/T molar ratio is beyond 7:3 or below 4:6, there were no SL-A/SB-A precursor transitions within 72 h solvent treatment for silica gels. The superhydrophilicity or superhydrophobicity of the obtained aerogels are constant and can’t be regulated by solvents (Supplementary Fig. 16). Because when MTMS is greatly excessive, the density of -CH3 groups in the aerogel becomes excessive, resulting in a high proportion of hydrophobic groups and consequently yielding only hydrophobic aerogels either in ethanol or water. For example, water contact angle of silica aerogels synthesized with pure MTMS under ethanol as solvent can reach 152.7° ± 3.0°. After subjecting the silica SB-A precursor to water treatment at 80 °C for 360 h, water contact angles of obtained silica aerogels still maintain 125.8° ± 2.6° (Supplementary Fig. 17). Conversely, in the presence of a significant excess of TMOS, the density of -OH in the aerogel becomes excessive, resulting in an inadequate generation of hydrophobic -OEt within 72 h during esterification for the transition from hydrophilic aerogel precursors to hydrophobic aerogel precursors. (Fig. 1, Supplementary Fig. 18). For instance, the water contact angles of silica aerogels synthesized using pure TMOS as a precursor in ethanol solvent were found to be 0°. Even after subjecting the silica SB-A precursor to ethanol treatment at 80 °C for 360 h, water contact angles of obtained silica aerogels remained unchanged at 0° (Supplementary Fig. 19). Besides the M/T molar ratio, the initial state of the precursor also affects the SL-A/SB-A precursor transition time. For example, compared with Fig. 2d, the SL-A precursor in Fig. 3c has a longer hydrophobic period. This may be due to that the SL-A precursor prepared with water as a solvent (Fig. 3c) has more surface Si-OH groups than the SL-A precursor prepared by incomplete hydrolysis of the SB-A precursor (Fig. 2d).

所有结果证实,在制备超疏水二氧化硅气凝胶过程中,80°C 乙醇中 Si-OH 与乙醇之间的酯化反应生成了疏水的 Si-OCH 2 -CH 3 基团。而在制备超亲水二氧化硅气凝胶过程中,80°C 水中 Si-OCH 2 -CH 3 的水解生成了更多的亲水基团。此外,需要注意的是,酯化和水解是实现可逆的 SL-A/SB-A 前驱体转变的必要但不充分条件。M/T 摩尔比和反应时间是另外两个重要因素。当 M/T 摩尔比超过 7:3 或低于 4:6 时,在 72 小时溶剂处理二氧化硅凝胶的过程中不会发生 SL-A/SB-A 前驱体转变。所获得的气凝胶的超亲水性或超疏水性是恒定的,无法通过溶剂进行调节(补充图 16)。因为当 MTMS 过量时,气凝胶中的-CH 3 基团密度过高,导致大量疏水基团的存在,从而在乙醇或水中仅生成疏水气凝胶。 例如,使用纯 MTMS 作为前驱体,在乙醇作为溶剂合成的二氧化硅气凝胶的水接触角可达到 152.7°±3.0°。经过 80°C 下水处理 360 小时后,所得二氧化硅气凝胶的水接触角仍保持在 125.8°±2.6°(补充图 17)。相反,在 TMOS 过量的情况下,气凝胶中的-OH 密度过高,导致在酯化反应的 72 小时内,从亲水气凝胶前驱体转变为疏水气凝胶前驱体时,生成的疏水-OEt 不足。例如,使用纯 TMOS 作为前驱体在乙醇溶剂中合成的二氧化硅气凝胶的水接触角为 0°。即使经过 80°C 下乙醇处理 360 小时后,所得二氧化硅气凝胶的水接触角仍保持在 0°(补充图 19)。除了 M/T 摩尔比外,前驱体的初始状态也会影响 SL-A/SB-A 前驱体转变的时间。例如,与图 2d 相比,图 3c 中的 SL-A 前驱体具有更长的疏水期。 这可能是因为使用水作为溶剂制备的 SL-A 前驱体(图 3c)比通过不完全水解 SB-A 前驱体制备的 SL-A 前驱体具有更多的表面 Si-OH 基团(图 2d)。

Transitions universality and on-demand sorption

普适性与按需吸附

For the synthesis of silica aerogels, various silica precursors are commonly employed. The universality of solvent-regulated SB-A/SL-A precursor transitions and on-demand superhydrophobicity/superhydrophilicity of silica aerogels was validated by selecting different silica precursors, such as MTMS/TEOS and SMS/TMOS, with various molar ratios. (Fig. 5 a–c). For instance, the water contact angles of hydrophobic silica aerogels synthesized using molar ratios of MTMS/TEOS (7:3–4:6) ranged between 133.9° ± 2.0° and 140° ± 1.4°. Subsequent water treatment for SB-A precursor resulted silica aerogels with a reduction of the water contact angles to 0°, rendering the material completely hydrophilic (Fig. 5b). The silica aerogel prepared using SMS and TMOS exhibit a similar phenomenon. (Fig. 5c). These results indicate that not only precursors like MTMS and TMOS with such molar ratios, but also MTMS/TEOS and SMS/TMOS could fabricate silica aerogels with on-demand hydrophobicity/hydrophilicity (Supplementary Table 1).

对于二氧化硅气凝胶的合成,通常会使用各种硅前驱体。通过选择不同的硅前驱体,如 MTMS/TEOS 和 SMS/TMOS,并采用不同的摩尔比,验证了溶剂调节的 SB-A/SL-A 前驱体转换和二氧化硅气凝胶的按需超疏水/超亲水性(图 5a-c)。例如,使用 MTMS/TEOS(7:3-4:6)摩尔比合成的疏水二氧化硅气凝胶的水接触角在 133.9°±2.0°至 140°±1.4°之间。随后对 SB-A 前驱体进行水处理,可使水接触角降至 0°,从而使材料完全亲水(图 5b)。使用 SMS 和 TMOS 制备的二氧化硅气凝胶也表现出类似的现象(图 5c)。这些结果表明,不仅像 MTMS 和 TMOS 这样的摩尔比前驱体,MTMS/TEOS 和 SMS/TMOS 也能制备具有按需疏水/亲水性的二氧化硅气凝胶(补充表 1)。

图 5:溶剂调节 SB-A/SL-A 前驱体转变的普适性及相应超疏水和超亲水硅气凝胶的按需应用。

SB-A superhydrophobic aerogel, SL-A superhydrophilic aerogel. a Chemical structures of diverse silica precursor mixtures for switchable SL-A/SB-A precursor transitions. MTMS trimethoxymethylsilane, TMOS tetramethoxysilane, TEOS tetraethyl orthosilicate, SMS sodium methicosilicate. b Water contact angles of MTMS/TEOS silica aerogels obtained from initial SB-A precursors and water-induced SL-A precursors. c Water contact angles of SMS/TMOS silica aerogels obtained from initial SL-A precursors and ethanol-induced SB-A precursors. d UV-vis spectra of residual MB in dichloromethane during adsorbing by superhydrophobic silica aerogels. MB: methylene blue. e Final residual concentrations of MB in dichloromethane after adsorbed by superhydrophobic silica aerogels and superhydrophilic ones. Error bar: <0.13 μg/g. f Final residual concentrations of MB in water after adsorbed by superhydrophobic silica aerogels and superhydrophilic ones. Error bar: <0.53 μg/g. g Photographs of MB in dichloromethane (below layer) and water (upper layer) before adsorption (g1) and after adsorbed by superhydrophobic silica aerogels (below layer) and superhydrophilic ones (upper layer) (g2). Scale bar: 1 cm. h Self-cleaning properties of superhydrophobic silica aerogels. Scale bar: 0.5 cm. i droplet resilience of superhydrophobic silica aerogels. Volume of water droplet is 10 μL. Scale bar: 1 cm. Source data are provided as a Source Data file.

SB-超疏水气凝胶,SL-超亲水气凝胶。a 可切换 SL-A/SB-A 前驱体的多种硅前驱体混合物的化学结构。MTMS 三甲氧基甲硅烷,TMOS 四甲氧基硅烷,TEOS 四乙氧基硅烷,SMS 甲基硅酸钠。b 从初始 SB-A 前驱体和水诱导 SL-A 前驱体获得的 MTMS/TEOS 硅气凝胶的水接触角。c 从初始 SL-A 前驱体和乙醇诱导 SB-A 前驱体获得的 SMS/TMOS 硅气凝胶的水接触角。d 超疏水硅气凝胶吸附甲基蓝后二氯甲烷中剩余的紫外-可见光谱。MB:甲基蓝。e 超疏水硅气凝胶和超亲水硅气凝胶吸附后甲基蓝在二氯甲烷中的最终残留浓度。误差条:<0.13 μg/g。f 超疏水硅气凝胶和超亲水硅气凝胶吸附后甲基蓝在水中的最终残留浓度。误差条:<0.53 μg/g。g 甲基蓝在二氯甲烷(下层)和水(上层)中的照片,吸附前(g 1 )和吸附后(超疏水硅气凝胶下层,超亲水硅气凝胶上层)(g 2 )。 尺:1 cm. h 超疏水二氧化硅气凝胶的自清洁性能。尺:0.5 cm. i 超疏水二氧化硅气凝胶的水滴弹跳性能。水滴体积为 10 μL。尺:1 cm. 数据源文件中提供了数据源。

Additionally, apart from ethanol, other alcohols such as methanol and isopropanol can also facilitate the formation of hydrophobic aerogels by converting SL-A precursors into SB-A precursors at 80 °C for 72 h. However, only treatment with methanol and ethanol during the solvent treatment process induces the formation of hydrophobic aerogels exhibiting water contact angles of 152.8° and 151.8° respectively. On the contrary, isopropanol only results in aerogels with a water contact angle of 98.3°; whereas isobutanol proves ineffective in achieving hydrophobization. (Supplementary Fig. 20) This phenomenon may be due to the different reactivity between alcohols and Si-OH (methanol > ethanol > isopropanol > isobutanol)43.

此外,除了乙醇,甲醇和异丙醇也可以促进疏水气凝胶的形成,通过在 80°C 下处理 72 小时将 SL-A 前驱体转化为 SB-A 前驱体。然而,只有在溶剂处理过程中使用甲醇和乙醇才能诱导形成水接触角分别为 152.8°和 151.8°的疏水气凝胶。相反,异丙醇仅导致水接触角为 98.3°的气凝胶;而异丁醇则无法实现疏水化。(补充图 20)这一现象可能与不同醇类对 Si-OH 的反应性不同(甲醇>乙醇>异丙醇>异丁醇)有关。

The application of aerogels in various scenarios is closely linked to the surface attribute of aerogels, encompassing adsorption44, catalysis5, separation45, filtration46, surface modification30, and more. Achieving on-demand superhydrophobicity/superhydrophilicity plays a pivotal role in enhancing the application adaptability of aerogels. For example, aerogels were usually used to adsorb dyes in water/oil mixtures47. However, for unknown pigments and adsorption conditions, we need to evaluate and select aerogels with suitable surface attribute for efficient adsorption. In our model, we use methylene blue (MB) as dye, water as aqueous phase, and dichloromethane as the oil phase to evaluate the difference in dye adsorption capacity by silica aerogels with different surface attributes. Superhydrophobic silica aerogels exhibit superior adsorptive properties for MB in dichloromethane than superhydrophilic ones (Fig. 5d, e and Supplementary Fig. 21) as evidenced by the lower residual concentrations of MB in dichloromethane after adsorption by the SB-As with residual concentration of 0.88 ppm compared to the superhydrophilic ones with residual concentration of 2.61 ppm, according to standard curves of dye concentration verse absorbance intensity (Supplementary Fig. 22). Nevertheless, only superhydrophilic silica aerogels can totally absorb MB in aqueous phase while superhydrophobic ones display negligible adsorption for dyes, with the residual concentrations of MB 0.50 ppm and 9.38 ppm respectively (Fig. 5f and Supplementary Fig. 23). The adsorption kinetics48 of MB in oil and water suggest that the adsorption process is likely a synergy between physical adsorption and chemical adsorption (Supplementary Figs. 24–26 and Supplementary Table 2). The adsorption efficiency in oil-water mixing system can be enhanced by employing a combination of hydrophilic and hydrophobic aerogels, or by designing and applying aerogels with an appropriate level of surface attribute through controlled solvent treatment time. As exhibited in Fig. 5g, a clear solution was obtained after MB in the oil phase being adsorbed by superhydrophobic silica aerogels and the dye in the aqueous phase being adsorbed by superhydrophilic ones (Fig. 5g2).

气凝胶在各种场景中的应用与其表面属性密切相关,包括吸附 44 、催化 5 、分离 45 、过滤 46 、表面改性 30 等。实现按需的超疏水/超亲水性能对于提高气凝胶的应用适应性至关重要。例如,气凝胶通常用于吸附水/油混合物中的染料 47 。然而,对于未知的染料和吸附条件,我们需要评估并选择具有合适表面属性的气凝胶以实现高效的吸附。在我们的模型中,我们使用甲基蓝(MB)作为染料,水作为水相,二氯甲烷作为油相,来评估不同表面属性的硅气凝胶对 MB 吸附能力的差异(图 5d、e 和补充图)。 21) 如标准曲线(染料浓度与吸光度强度)所示(补充图 22),在二氯甲烷中吸附后,SB-As 的残留浓度为 0.88 ppm,而超亲水型的残留浓度为 2.61 ppm,这表明 SB-As 的残留浓度较低。然而,只有超亲水型硅气凝胶能在水相中完全吸附 MB,而超疏水型气凝胶对染料的吸附几乎可以忽略不计,残留浓度分别为 0.50 ppm 和 9.38 ppm(图 5f 和补充图 23)。油水体系中 MB 的吸附动力学表明,吸附过程可能是物理吸附和化学吸附的协同作用(补充图 24-26 和补充表 2)。通过结合亲水和疏水气凝胶,或通过控制溶剂处理时间设计和应用具有适当表面属性的气凝胶,可以在油水混合体系中提高吸附效率。如图所示(图中未完全展示)。 5g,油相中的 MB 被超疏水硅气凝胶吸附,水相中的染料被超亲水硅气凝胶吸附,从而得到清晰的溶液(图 5g 2 )。

Besides in dye adsorption, SB-As are generally considered to be suitable materials for self-cleaning, that can be disastrous for SL-As49. As illustrated in Fig. 5h, muddy water on the surface of SB-As can be completely absorbed by absorbent paper without any residual pollutants. Moreover, once the falling water droplet touches the superhydrophobic surface of silica aerogels, it will rebound to a certain height (Fig. 5i and Supplementary Movie 1). While upon contact with muddy water, SL-As rapidly disintegrated, as depicted in Supplementary Fig. 27. All such results indicate self-cleaning property of superhydrophobic silica aerogels. Moreover, superhydrophobic silica aerogels also exhibit high oil-water separation efficiency in environments such as strong acids and bases (Supplementary Fig. 28 and Supplementary Table 3).

除了在染料吸附中,SB-As 通常被认为适合自清洁应用,这对 SL-As 来说可能是灾难性的。如图 5h 所示,SB-As 表面的泥水可以被吸水纸完全吸收,没有任何残留污染物。此外,一旦水滴接触到二氧化硅气凝胶的超疏水表面,它会弹跳到一定高度(图 5i 和补充视频 1)。而当接触到泥水时,SL-As 会迅速分解,如补充图 27 所示。所有这些结果表明超疏水二氧化硅气凝胶具有自清洁性能。此外,超疏水二氧化硅气凝胶在强酸和强碱等环境中也表现出高效的油水分离效率(补充图 28 和补充表 3)。

Comparison between traditional synthesis and our strategy

传统合成与我们的策略比较

Compared to the conventional hydrophobic modification method of silica aerogels, the utilization of water/ethanol for solvent-regulated surface attributes in aerogels offers significant advantages. Currently, the conventional hydrophobic modification of silica aerogels typically involves the addition of hydrophobic modification reagents to the reaction system50, thereby necessitating a subsequent complex process to remove excess reagents. In contrast, this study demonstrates a more convenient and simplified approach by achieving switchable hydrophilic and hydrophobic modification through direct solvent heating. Based on this, we can realize the rapid and large-scale modification of hydrophilic and hydrophobic aerogels (Fig. 6a).

与传统的二氧化硅气凝胶疏水改性方法相比,利用水/乙醇调节气凝胶的溶剂可控表面属性具有显著优势。目前,传统的二氧化硅气凝胶疏水改性通常需要向反应体系中加入疏水改性试剂 50 ,从而需要后续复杂的步骤来去除多余的试剂。相比之下,本研究通过直接加热溶剂实现了可切换的亲水和疏水改性,提供了一种更便捷和简化的途径。基于此,我们能够实现快速和大规模的亲水和疏水气凝胶改性(图 6a)。

图 6:传统合成与我们的策略比较。

a Large-scale production of aerogels with our strategy. b Hydrophobic aerogel to hydrophilic one in water vapor. SB-A superhydrophobic aerogel. c Hydrophilic aerogel to hydrophobic one in ethanol vapor. SL-A superhydrophilic aerogel. d Physiological toxicity of common hydrophobic modification reagents used elsewhere and solvents used in this work. GHS classification Globally Harmonized System of Classification and Labeling of Chemicals, SAH/LAH short/long-term (acute/chronic) aquatic hazard, OT specific target organ toxicity, ED serious eye damage/irritation, SC skin corrosion/irritation, ATD acute toxicity (dermal), ATI acute toxicity (inhalation), ATO acute toxicity (oral), TMCS trimethylchlorosilane, HMDZ hexamethyldisilazane, HMDSO hexamethyldisiloxane. e Cost of common hydrophobic modification reagents used elsewhere and solvents used in this work. Source data are provided as a Source Data file.

a 采用我们的策略大规模生产气凝胶。b 气凝胶在水蒸气中从疏水变为亲水。SB-超疏水气凝胶。c 气凝胶在乙醇蒸气中从亲水变为疏水。SL-超亲水气凝胶。d 常见疏水改性试剂和本工作中使用的溶剂的生理毒性。GHS 分类 全球化学品统一分类和标签制度,SAH/LAH 短期/长期(急性/慢性)水生危害,OT 特定靶器官毒性,ED 严重眼损伤/刺激,SC 皮肤腐蚀/刺激,ATD 急性皮肤毒性,ATI 急性吸入毒性,ATO 急性口服毒性,TMCS 三甲基氯硅烷,HMDZ 六甲基二硅氮烷,HMDSO 六甲基二硅氧烷。e 常见疏水改性试剂和本工作中使用的溶剂的成本。源数据作为源数据文件提供。

Moreover, the conventional hydrophobic reaction of silica aerogels involves the utilization of a reactant containing hydrophobic groups to interact with the functional groups of silica51. This reaction is typically irreversible, thereby enabling solely hydrophobic modification while precluding any possibility of achieving hydrophilic modification. In this study, in addition to the switchable hydrophilic and hydrophobic modification in the liquid phase mentioned above, we also demonstrate the feasibility of achieving hydrophilic and hydrophobic modification in the gas phase. Under normal service environment, superhydrophobic silica aerogels show excellent hydrophobic stability (even at 100% humidity and 60–80 °C. Supplementary Fig. 29) and mechanical property stability. For example, the mechanical properties of silica samples remain unchanged after multiple precursor cycles, superhydrophilic-superhydrophobic conversion, and prolonged outdoor use (Supplementary Figs. 30–33 and Supplementary Tables 4–6). After 125 °C hot water steam treatment, the SB-A with the original capability of floating on the aqueous interface was immersed into water, indicating a transition from hydrophobicity to hydrophilicity on the aerogel surface with water contact angle changed from 148.0° to 46° (Fig. 6b). After subjecting the hydrophilic aerogel to high-temperature ethanol treatment, a notable transition from hydrophilicity with water contact angle 0° to hydrophobicity was observed, as evidenced by water contact angle 140° (Fig. 6c). This means that switchable hydrophobic modification of silica aerogel surfaces can be rapidly and efficiently achieved through this approach, eliminating the need for time-consuming solvent displacement and drying processes. Additionally, according to the Safety Data Sheet (Supplementary Table 7), the most hydrophobic modification agents are expensive and exhibit physiological toxicity such as acute toxicity, (oral/inhalation/dermal) (ATO/ATI/ATD), skin corrosion/irritation (SC), serious eye damage/irritation (ED), specific target organ toxicity (OT), short/long-term (acute/chronic) aquatic hazard (SAH/LAH). In contrast, compared to trimethylchlorosilane (TMCS), hexamethyldisilazane (HMDZ), hexamethyldisiloxane (HMDSO), etc. as the modification reagents52, ethanol and water are considered cost-effective and green solvents (Fig. 6d, e). Moreover, SB-As with static water contact angle (150.7°) and water sliding angle (3.3°) can also be obtained through ambient drying, showing specific surface area of 1084 m2/g without the need for Sc CO2 drying (Supplementary Fig. 34). This indicates that this work is at the same time a more green and economical hydrophobic modification method of silica aerogels. In summary, this work offers an environmentally friendly, cost-effective, and efficient approach for achieving switchable hydrophilic-hydrophobic modification.

此外,传统的硅气凝胶疏水反应涉及使用含有疏水基团的反应物与硅气凝胶的功能基团相互作用 51 。这种反应通常是不可逆的,因此仅能实现疏水改性,而无法实现亲水改性。在本研究中,除了上述在液相中实现可切换的亲水和疏水改性外,我们还展示了在气相中实现亲水和疏水改性的可行性。在正常服役环境中,超疏水硅气凝胶表现出优异的疏水稳定性(即使在 100%湿度和 60-80°C 下,补充图 29)和机械性能稳定性。例如,硅样品的机械性能在多次前驱体循环、亲水-疏水转换以及长时间户外使用后保持不变(补充图 30-33 和补充表 4-6)。 经过 125°C 热水蒸汽处理后,原本具有在水液界面漂浮能力的 SB-A 浸入水中,表明气凝胶表面从疏水性转变为亲水性,水接触角从 148.0°变为 46°(图 6b)。在将亲水性气凝胶进行高温乙醇处理后,观察到从 0°的亲水性到疏水性的显著转变,水接触角为 140°(图 6c)。这意味着,通过这种方法可以快速且高效地实现硅气凝胶表面的可切换疏水改性,从而省去了耗时的溶剂置换和干燥过程。此外,根据安全数据表(补充表 7),最疏水的改性剂价格昂贵,并且具有生理毒性,如急性毒性(经口/吸入/皮肤接触)(ATO/ATI/ATD)、皮肤腐蚀/刺激(SC)、严重眼损伤/刺激(ED)、特定靶器官毒性(OT)、短期/长期(急性/慢性)水生危害(SAH/LAH)。 相比之下,与三甲基氯硅烷(TMCS)、六甲基二硅氮烷(HMDZ)、六甲基二硅氧烷(HMDSO)等改性试剂相比,乙醇和水被认为是成本效益高且环保的溶剂(图 6d、e)。此外,通过常温干燥,也可以获得静态水接触角为 150.7°、水滑动角为 3.3°的 SB-As,其比表面积为 1084 m²/g,无需使用 Sc CO₂干燥(补充图 34)。这表明,这项工作同时提供了一种更环保和经济的二氧化硅气凝胶疏水改性方法。总之,这项工作提供了一种环保、成本效益高且高效的可切换亲水-疏水改性方法。

Discussion 讨论

In summary, silica aerogels with on-demand superhydrophobic/superhydrophilic properties are synthesized by precisely controlling the solvent composition (water/ethanol) during sol-gel transition and solvent exchange process. Reversible transitions between SB-A precursor and SL-A precursor induced by solvent exchange in ethanol and water respectively at 80 °C leads to on-demand superhydrophobic/superhydrophilic properties of silica aerogels. Changes either in synthetic routes or silica precursors, solvent-regulated SB-A/SL-A precursor transitions, and on-demand superhydrophobicity and superhydrophilicity consistently occur during the preparation of silica aerogels, demonstrating their universality. Mechanistic studies reveal that these switchable transitions are attributed to reversible esterification reactions between Si-OH groups and ethanol. Such solvent-regulable interfacial groups enable on-demand superhydrophobic/superhydrophilic silica aerogels in various applications including adsorption, etc. In conclusion, this article unveils a long-overlooked phenomenon: solvent-induced hydrophobization and hydrophilization in the field of silica aerogels, which serves as a significant wake-up call for practitioners working with these materials. Furthermore, this discovery offers an environmentally friendly, cost-effective, and efficient approach for aerogels to achieve switchable hydrophilic-hydrophobic modifications.

总之,通过精确控制溶胶-凝胶转变和溶剂交换过程中的溶剂组成(水/乙醇),合成了具有可需求超疏水/超亲水性能的二氧化硅气凝胶。在 80°C 下,通过乙醇和水中的溶剂交换分别诱导 SB-A 前驱体和 SL-A 前驱体的可逆转换,从而赋予二氧化硅气凝胶可需求的超疏水/超亲水性能。无论是合成路线还是二氧化硅前驱体的变化,溶剂调节的 SB-A/SL-A 前驱体转换以及可需求的超疏水性和超亲水性在制备二氧化硅气凝胶的过程中始终存在,证明了其普适性。机制研究表明,这些可切换的转换归因于 Si-OH 基团与乙醇之间的可逆酯化反应。这种溶剂可调节的界面基团使得二氧化硅气凝胶在吸附等各类应用中具有可需求的超疏水/超亲水性能。 总之,本文揭示了一个长期被忽视的现象:溶剂诱导的硅气凝胶疏水化和亲水化,这为这些材料的研究人员敲响了警钟。此外,这一发现为气凝胶提供了环保、经济且高效的可切换亲水-疏水改性方法。

Methods 方法

Materials 材料

Trimethoxymethylsilane (MTMS) (98%), Tetramethoxysilane (TMOS) (98%), and Tetraethyl orthosilicate (TEOS) (98%), Hydrochloric acid (HCl) (37%), Ammonia aqueous solution (NH3•H2O, 28–30%, ACS), Ethanol (ACS ≥ 99.5%), Methylene blue (Indicator grade) and Dichloromethane (AR, 99.5%) are purchased from Aladdin Industrial Corporation (Shanghai, China). Acetone (≥99.0%) is purchased from Sinopharm Chemical Reagent Co., Ltd (Shanghai, China).

三甲氧甲硅烷(MTMS,98%)、四甲氧基硅烷(TMOS,98%)、四乙氧基硅烷(TEOS,98%)、盐酸(HCl,37%)、氨水(NH4•H2O,28-30%,ACS)、乙醇(ACS ≥ 99.5%)、甲基蓝(指示剂级)和二氯甲烷(AR,99.5%)均购自阿拉丁工业有限公司(中国上海)。丙酮(≥99.0%)购自上海中化试剂有限公司。

Sodium methicosilicate (SMS) (AR, 30%) is purchased from Yuanye Bio-Technology Co., Ltd (Shanghai, China). Deionized water (18.2 MΩ cm−1) was obtained from a Millipore-Q system. All other reagents were used without further purification.

硅甲氧基甲基硅酸钠(SMS,AR,30%)购自优然生物科技有限公司(中国上海)。去离子水(18.2 MΩ cm)来自密理博-Q 系统。其他所有试剂均未进一步提纯。

Synthesis of the silica aerogels by MTMS and TMOS

MTMS 和 TMOS 制备硅气凝胶

To prepare silica aerogels, 2 mmol silica precursors with diverse molar ratios of MTMS and TMOS are added into 1 mL ethanol or water and followed with 130 μL 0.01 mol/L HCl and then stirred for 30 min at room temperature to form silica sol. Then 87 μL 2 mol/L NH3•H2O are added into the above sol and put at 80 °C for 2 days for sol-gel transitions and then complete gelling and aging processes to form silica organogel and hydrogel. Residues are removed before solvent treatment process. Solvent treatment process are based on replacing ethanol in organogel with 20 mL water 3 times to form hydrogel at 80 °C for diverse time periods or exchange water in hydrogel with 20 mL ethanol for 3 times to form organogel at 80 °C for diverse time periods.

制备硅气凝胶时,将不同摩尔比的 MTMS 和 TMOS 的 2 mmol 硅前驱体加入到 1 mL 乙醇或水中,随后加入 130 μL 0.01 mol/L HCl,室温搅拌 30 分钟以形成硅溶胶。然后向上述溶胶中加入 87 μL 2 mol/L NH4OH,80 °C 下固化 2 天,完成溶胶-凝胶转变、完全凝胶化和老化过程,形成有机硅气凝胶和水凝胶。溶剂处理前去除残留物。溶剂处理过程是通过三次将有机硅气凝胶中的乙醇替换为 20 mL 水,在 80 °C 下不同时间段形成水凝胶,或三次将水凝胶中的水替换为 20 mL 乙醇,在 80 °C 下不同时间段形成有机硅气凝胶。

Synthesis of the silica aerogels by MTMS and TEOS

通过 MTMS 和 TEOS 制备硅气凝胶

To hydrolyze TEOS, 1 mol TEOS and 34.2 mL 0.01 mol/L HCl were added to 234 mL ethanol and then stirred at 130 °C for 8 h to get transparent TEOS solution. To get silica organogel, 2 mmol silica precursors with diverse molar ratios of MTMS and TEOS are added into 1 mL ethanol and followed with 130 μL 0.01 mol/L HCl and stirred for 30 min at room temperature. Eighty-seven microlitre 2 mol/L NH3•H2O are added and put at 80 °C for 2 days to form organogel. Residues are removed before solvent treatment process.

为了水解 TEOS,向 234 mL 的乙醇中加入 1 mol TEOS 和 34.2 mL 0.01 mol/L 的 HCl,然后在 130 °C 下搅拌 8 小时,得到透明的 TEOS 溶液。为了制备有机硅凝胶,将不同 MTMS 和 TEOS 摩尔比的 2 mmol 硅前驱体加入 1 mL 乙醇中,随后加入 130 μL 0.01 mol/L 的 HCl,并在室温下搅拌 30 分钟。然后加入 87 μL 2 mol/L 的 NH 3 •H 2 O,80 °C 下放置 2 天以形成有机硅凝胶。在溶剂处理过程前去除残留物。

Solvent treatment process is based on replacing ethanol in organogel with 20 mL water for 3 times to form hydrogel at 80 °C for 72 h.

溶剂处理过程是基于将有机硅凝胶中的乙醇分三次替换为 20 mL 的水,在 80 °C 下放置 72 小时以形成水凝胶。

Synthesis of the silica aerogels by SMS and TMOS

硅气凝胶的 SMS 和 TMOS 合成

To get silica hydrogel, 2 mmol silica precursors with diverse molar ratios of SMS and TMOS are added into 1 mL water and followed with 360 μL 10 mol/L HCl and put at 80 °C for 2 days for sol-gel transitions to form hydrogel. Sodium salt was removed by water before solvent treatment process. Solvent treatment process is based on replacing water in hydrogel with 20 mL ethanol for 3 times to form organogel at 80 °C for 72 h.

为了制备硅水凝胶,将不同 SMS 和 TMOS 摩尔比的 2 mmol 硅前驱体加入 1 mL 水中,随后加入 360 μL 10 mol/L 的 HCl,并在 80 °C 下放置 2 天以完成溶胶-凝胶转变,形成水凝胶。在溶剂处理过程前通过水去除钠盐。溶剂处理过程是基于将水凝胶中的水分三次替换为 20 mL 的乙醇,在 80 °C 下放置 72 小时以形成有机硅凝胶。

Synthesis of the silica aerogels by MTMS

通过 MTMS 合成硅气凝胶

To prepare pure MTMS silica aerogels, 2 mmol MTMS are added into 1 mL ethanol and followed with 130 μL 0.01 mol/L HCl and then stirred for 30 min at room temperature to form silica sol. Then 87 μL 2 mol/L NH3•H2O are added into the above sol and put at 80 °C for 2 days for sol-gel transitions and then complete gelling and aging processes to form silica organogel. Residues are removed before solvent treatment process. Solvent treatment process is based on replacing ethanol in silica organogel with 20 mL water for 3 times to form hydrogel at 80 °C for diverse days.

为了制备纯 MTMS 硅气凝胶,将 2 mmol MTMS 加入 1 mL 乙醇中,随后加入 130 μL 0.01 mol/L HCl,然后在室温下搅拌 30 分钟以形成硅溶胶。接着向上述溶胶中加入 87 μL 2 mol/L NH4OH,然后在 80 °C 下放置 2 天进行溶胶-凝胶转变,随后完成凝胶化和老化过程,形成硅有机气凝胶。在溶剂处理过程中去除残留物。溶剂处理过程是通过将硅有机气凝胶中的乙醇分三次替换为 20 mL 水,在 80 °C 下放置不同天数,以形成水凝胶。

Synthesis of the silica aerogels by TMOS

TMOS 法制备硅气凝胶

To prepare pure TMOS silica aerogels, 2 mmol TMOS are added into 1 mL ethanol and followed with 130 μL 0.01 mol/L HCl and then stirred for 30 min at room temperature to form silica sol. Then 87 μL 2 mol/L NH3•H2O are added into the above sol and put at 80 °C for 2 days for sol-gel transitions and then complete gelling and aging processes to form TMOS silica organogel. Residues are removed before solvent treatment process. Solvent treatment process is based on replacing ethanol in TMOS silica organogel with 20 mL ethanol for 3 times to form TMOS silica organogel at 80 °C for diverse days.

为了制备纯净的 TMOS 硅气凝胶,将 2 mmol TMOS 加入 1 mL 乙醇中,随后加入 130 μL 0.01 mol/L HCl,然后在室温下搅拌 30 分钟,形成硅溶胶。接着向上述溶胶中加入 87 μL 2 mol/L NH4OH,然后在 80 °C 下放置 2 天进行溶胶-凝胶转变,随后完成凝胶化和老化过程,形成 TMOS 硅有机气凝胶。在溶剂处理过程前去除残留物。溶剂处理过程是通过将 TMOS 硅有机气凝胶中的乙醇替换为 20 mL 乙醇,共进行 3 次,然后在 80 °C 下放置不同天数,形成 TMOS 硅有机气凝胶。

Detailed Sc drying conditions

详细的 Sc 干燥条件

Sc CO2 drying is generally applied to get silica aerogel in industry. In order to get ideal silica aerogel structure, ethanol is commonly selected as an exchange solvent for gels before putting them in Sc reactor. In order to exclude the influence of ethanol on aerogel properties during Sc drying, all wet gels were solvent exchanged with acetone before Sc drying at least 6 times at room temperature for 2 days to ascertain complete removal of ethanol before Sc drying (Supplementary Fig. 35). Acetone gel was dried in circulating Sc CO2 fluids at 40 °C and 10 MPa for at least 10 h with a flow rate exceeding 6 L/h to ensure complete replacement of acetone by Sc CO2 fluid. Depressurization was initiated only after no further release of acetone from the gas vent and continued for at least 5 h to facilitate degassing. Under these optimized conditions, our aerogels exhibited no residual traces of acetone.

溶剂共蒸发干燥(Sc CO 2 drying)通常用于工业生产硅气凝胶。为了获得理想的硅气凝胶结构,通常会在将凝胶放入 Sc 反应器之前,用乙醇作为交换溶剂替换凝胶。为了排除乙醇在 Sc 干燥过程中对气凝胶性能的影响,在 Sc 干燥前,所有湿凝胶至少在室温下用丙酮交换 6 次,连续 2 天,以确保完全去除乙醇(补充图 35)。然后在 40°C 和 10 MPa 的循环 Sc CO 2 流体中干燥丙酮凝胶,流速超过 6 L/h,至少干燥 10 小时,以确保丙酮被 Sc CO 2 流体完全替换。只有在从气相出口不再释放丙酮后,才开始减压,并继续至少 5 小时以促进脱气。在这些优化条件下,我们的气凝胶中没有残留丙酮的痕迹。

Dye adsorption 染料吸附

Prepare 0.010 mg/g methylene blue aqueous solution and 0.010 mg/g methylene blue/dichloromethane solution, respectively. Thirty milligrams SL or SB-A were used to adsorb dye in a 3 g solution for various periods. Then detect residue concentration of methylene blue in solution by UV-vis. Three samples were tested to calculate the average value and standard deviations. Calculation of dye concentration is based on establishing a standard curve between absorbance intensity and dye of known concentration based on the Lambert-Beer law, which means a linear correlation between the absorbance intensity and dye concentration.

制备 0.010 mg/g 的甲基蓝水溶液和 0.010 mg/g 的甲基蓝/二氯甲烷溶液,分别。使用 30 毫克 SL 或 SB-A 吸附不同时间 3 g 溶液中的染料。然后通过紫外-可见光谱检测溶液中剩余的甲基蓝浓度。测试三个样品以计算平均值和标准偏差。染料浓度的计算基于朗伯-比尔定律建立的吸光度强度与已知浓度染料之间的标准曲线,这意味着吸光度强度与染料浓度之间存在线性关系。

Separation efficiency of oil-water emulsion

油水乳状液的分离效率

The oil in water emulsion was prepared by adding 5 mL n-hexane, 0.1 g Tween 80 into 95 mL water and stirred for 2 h. Add 80 mg superhydrophobic silica aerogel into 5 mL oil in water emulsion prepared before and stir for 2 h to remove oil in emulsion. The pH value of 5 mL oil in water emulsion is regulated by adding 20 μL HCl to reach pH = 2 or ammonia to reach pH = 13. Then analyze the total organic carbon (TOC) content of the emulsion before and after separation by the TOC Analyzer. All samples were diluted by 200 times by adding 200 μL sample solution into 20 mL water (v/v). Three samples were tested to calculate the average value and standard deviation.

水包油乳液是通过向 95 mL 水中加入 5 mL 正己烷和 0.1 g 吐温 80,并搅拌 2 小时制备的。将 80 mg 超疏水硅气凝胶加入之前制备的 5 mL 水包油乳液中,并搅拌 2 小时以去除乳液中的油。通过向 5 mL 水包油乳液中加入 20 μL 盐酸调节 pH 值至 2,或加入氨水调节 pH 值至 13。然后使用 TOC 分析仪分析分离前后乳液的总有机碳(TOC)含量。所有样品通过将 200 μL 样品溶液加入 20 mL 水中(体积比)稀释 200 倍。测试三个样品以计算平均值和标准偏差。

Oil-water separation can be calculated by testing TOC concentration before and after emulsion separation. The equation of separation efficiency53 can be determined as:

通过测试分离前后乳液的 TOC 浓度可以计算油水分离效率。分离效率 53 的计算公式为:

Here, represents the separation efficiency, and means the TOC concentration in the emulsion before separation and after separation.

其中,\(R\) 表示分离效率,\({{\bf{C}}}_{{{\bf{0}}}}\) 和 \(C\) 分别表示分离前和分离后乳液中的 TOC 浓度。

Characterization 表征

Water contact angles of silica aerogels are tested by an optical contact angle goniometer (OCA 15EC, Data Physics Instruments, Germany) with 5 μL water. The static water contact angle and water sliding angle of droplets on sample surface were started to be measured after the water droplet contacted the surface of the samples for 20 s. Water sliding angle were tested by tilting the surfaces at a slow rate of 0.1°/s and the water sliding angle is defined as critical tilted angle which droplets start the continuous motion on the sample surface within 1 s. Three samples were tested to calculate the average value and standard deviation. Specific surface areas and pore size distributions are tested by the BET and Barrett–Joyner–Halenda methods based on nitrogen adsorption and desorption curves (ASAP 2020, Micromeritics, USA). Aerogels need to be outgassed at 120 °C for 4 h before further measurements. Three samples were tested to calculate the average value and standard deviation. The micro-morphologies and microstructures of silica aerogels are characterized by scanning electron microscopy (SEM, Hitachi S-4800, Japan) at 5 kV acceleration voltage. Size distribution of secondary particles of silica aerogel was analyzed by Nano Measure software based on the captured SEM images29. Si and 13C superconducting NMR spectra are tested by a solid superconducting NMR spectrometer (NMR, JEOL JNM-ECZ600R, Japan) at 80.0 Hz. Chemical structure of silica aerogels are measured by a Fourier Transform Infrared Spectroscopy (FTIR, 5700, FL, USA) equipped with attenuated total reflection (ATR) accessory over 64 scans measured with a resolution wavelength of 4 cm−1. Both superhydrophobic and SL-A samples were dried in a vacuum oven prior to testing and subsequently tested and analyzed in a dry environment quickly. During data analysis, the interference peak from water vapor in the background air was corrected. Consequently, the likelihood of hydroxyl vibration deviation due to atmospheric moisture during testing is minimal. Dynamic process of water droplets is captured by high-speed camera (VW-9000C) with 5 μL water dropping from a height of 20 cm. Absorbance of methylene blue solution is measured by an Ultraviolet-visible near infrared spectroscopy (UV−vis−NIR, Cary5000, Agilent, USA) within range of 300–900 nm. Gas chromatogram of acetone and ethanol mixture is measured by the gas chromatograph-mass spectrometer (GC-MS QP2010SE, SIMADZU) with Rtx-5MS chromatographic column and gas temperature holds at 40 °C for 1 min and then increase at 5 °C/min to 200 °C and then maintain for 5 min to test samples. Morphologies and size distribution of primary particles of silica aerogel were characterized on a Tecnai G2 F20 S-TWIN high-resolution transmission electron microscopy (FEI, USA) (TEM) with 200 kV acceleration voltage. Size distribution of primary particles of silica aerogel was analyzed by Nano Measure software based on the captured TEM images. The sample was prepared by homogeneously dispersing the silica aerogel in ethanol and ultrasonicating for 2 h. Then dipping the dispersion onto the thin carbon film and drying it in a vacuum oven for 6 h. The mechanical properties of aerogels were tested by a tensile testing machine (Instron 3365, ITW, USA). The measured sample for a compression test is a cylinder with a height of 7 mm and a radius of 23 mm. Three samples were tested to calculate the average value and standard deviation. The surface roughness of the samples was measured by 3D confocal microscopy with magnification (×150) (VK-X200, Keyence) by focusing on the surface of the samples. The captured images are 95 μm on x-axis and 75 μm on y-axis. Three samples were tested to calculate the average value and standard deviation. TOC content of oil in water emulsion before and after separation by silica aerogel was analyzed by the TOC Analyzer (O-I-Analytical, USA).

通过光学接触角测量仪(OCA 15EC,Data Physics Instruments,德国)测试二氧化硅气凝胶的水接触角,使用 5 μL 的水。在水滴接触样品表面 20 秒后,开始测量静态水接触角和液滴在样品表面的滑动角。滑动角通过以 0.1°/s 的速度倾斜表面进行测试,并定义为液滴在 1 秒内开始在样品表面连续运动的临界倾斜角度。测试三个样品以计算平均值和标准偏差。比表面积和孔径分布通过基于氮吸附和脱附曲线的 BET 和 Barrett–Joyner–Halenda 方法进行测试(ASAP 2020,Micromeritics,美国)。在进一步测量前,气凝胶需在 120 °C 下脱气 4 小时。测试三个样品以计算平均值和标准偏差。通过加速电压为 5 kV 的扫描电子显微镜(SEM,Hitachi S-4800,日本)表征二氧化硅气凝胶的微观形态和微观结构。 基于捕获的 SEM 图像,使用 Nano Measure 软件分析了硅气凝胶次级颗粒的粒径分布。Si 和 13 C 的超导核磁共振谱(NMR,JEOL JNM-ECZ600R,日本)在 80.0 Hz 下由固体超导核磁共振光谱仪测试。使用配备衰减全反射(ATR)附件的傅里叶变换红外光谱仪(FTIR,5700,FL,美国)在 64 次扫描中测量硅气凝胶的化学结构,分辨波长为 4 cm⁻¹。超疏水和 SL-A 样品在测试前均在真空烘箱中干燥,并在干燥环境中迅速进行测试和分析。在数据分析过程中,对背景空气中的水蒸气干扰峰进行了校正,从而在测试过程中由于大气湿度导致羟基振动偏移的可能性最小。高速摄像机(VW-9000C)以 5 μL 水从 20 cm 高度滴落的方式捕捉了水滴的动态过程。在 300–900 nm 范围内,使用紫外-可见-近红外分光光度计(UV−vis−NIR,Cary5000,Agilent,美国)测量甲基蓝溶液的吸光度。 通过气相色谱-质谱仪(GC-MS QP2010SE,SHIMADZU)使用 Rtx-5MS 色谱柱测量乙酸乙酯和乙醇混合物的气相色谱图,气相温度在 40 °C 保持 1 分钟,然后以 5 °C/min 的速度升至 200 °C,并保持 5 分钟以测试样品。使用 Tecnai G2 F20 S-TWIN 高分辨率透射电子显微镜(FEI,美国)(TEM)和 200 kV 加速电压表征硅气凝胶初级粒子的形态和尺寸分布。基于捕获的 TEM 图像,使用 Nano Measure 软件分析硅气凝胶初级粒子的尺寸分布。样品制备方法为:均匀分散硅气凝胶于乙醇中并超声处理 2 小时,然后将分散液滴在薄碳膜上,在真空烘箱中干燥 6 小时。气凝胶的机械性能通过 Instron 3365(ITW,美国)拉伸试验机进行测试。压缩测试的测量样品为高 7 mm、半径 23 mm 的圆柱体。进行了三个样品的测试以计算平均值和标准偏差。 样品的表面粗糙度通过 3D 共焦显微镜(放大倍数×150,VK-X200,Keyence)测量,聚焦于样品表面。捕获的图像在 x 轴上为 95 μm,在 y 轴上为 75 μm。测试了三个样品以计算平均值和标准偏差。通过 TOC 分析仪(O-I-Analytical,美国)分析油水乳液在使用硅气凝胶分离前后油的 TOC 含量。

Data availability 数据可用性

The data supporting the findings are provided within this Article and its Supplementary Information. Extra data are available from the corresponding authors upon request. Source data are provided with this paper.

支持研究发现的数据包含在本文及其补充信息中。额外数据可在请求时从相应作者处获得。随论文提供源数据。

References 参考文献

Sheng, Z. et al. The rising aerogel fibers: status, challenges, and opportunities. Adv. Sci. 10, 2205762 (2023).

盛, Z. 等. 上升的气凝胶纤维:现状、挑战与机遇. 进展科学 10, 2205762 (2023).Wu, M. et al. Biomimetic, knittable aerogel fiber for thermal insulation textile. Science 382, 1379–1383 (2023).

吴, M. 等. 生物仿生可编织气凝胶纤维用于隔热纺织品. 科学 382, 1379–1383 (2023).Guo, J. et al. Hypocrystalline ceramic aerogels for thermal insulation at extreme conditions. Nature 606, 909–916 (2022).

郭, J. 等. 极端条件下具有隔热性能的低结晶陶瓷气凝胶. 自然 606, 909–916 (2022).Li, D. et al. Double-helix structure in carrageenan–metal hydrogels: a general approach to porous metal sulfides/carbon aerogels with excellent sodium-ion storage. Angew. Chem. Int. Ed. 55, 15925–15928 (2016).

李等. 琼胶–金属水凝胶中的双螺旋结构:优异钠离子存储性能的多孔金属硫化物/碳气凝胶的通用制备方法.《德国应用化学》55, 15925–15928 (2016).Li, Z. et al. Atomic aerogel materials (or single-atom aerogels): an interesting new paradigm in materials science and catalysis science. Adv. Mater. 35, 2211221 (2023).

Li, Z. 等. 原子气凝胶材料(或单原子气凝胶):材料科学和催化科学中的一个有趣的新范式。先进材料 35, 2211221 (2023)。Ali, E. et al. Giant-stroke, superelastic carbon nanotube aerogel muscles. Science 5921, 1575–1578 (2009).

Ali, E. 等. 巨大行程、超弹性碳纳米管气凝胶肌肉。科学 5921, 1575–1578 (2009)。Wang, C. et al. Closed-loop recyclable high-performance polyimine aerogels derived from bio-based resources. Adv. Mater. 35, 2209003 (2023).

Wang, C. 等. 来源于生物基资源的闭环可回收高性能聚酰亚胺气凝胶。先进材料 35, 2209003 (2023)。Li, C. et al. Silica aerogels: from materials research to industrial applications. Int. Mater. Rev. 68, 862–900 (2023).

Li, C. 等. 硅气凝胶:从材料研究到工业应用。国际材料评论 68, 862–900 (2023)。Wang, F. et al. Biomimetic and superelastic silica nanofibrous aerogels with rechargeable bactericidal function for antifouling water disinfection. ACS Nano 14, 8975–8984 (2020).

王锋等. 具有可充电杀菌功能的仿生超弹性硅酸盐纳米纤维气凝胶用于防污水消毒. ACS 纳米 14, 8975–8984 (2020).Zhao, S. et al. Additive manufacturing of silica aerogels. Nature 584, 387–392 (2020).

赵帅等. 硅酸盐气凝胶的增材制造. 自然 584, 387–392 (2020).Ji, X. et al. Ratio-tuning of silica aerogel co-hydrolyzed precursors enables broadband, angle-independent, deformation-tolerant, achieving 99.7% reflectivity. Small 19, 2301534 (2023).

姬旭等. 调节硅酸盐气凝胶共水解前驱体的比例实现宽带、角度无关、变形耐受的 99.7%反射率. 小微 19, 2301534 (2023).Mazrouei-Sebdani, Z. et al. A review on silica aerogel-based materials for acoustic applications. J. Non Cryst. Solids 562, 120770 (2021).

马祖伊-赛班尼等. 基于硅酸盐气凝胶材料的声学应用综述. 非晶态固体 562, 120770 (2021).Lin, J. et al. A review of recent progress on the silica aerogel monoliths: synthesis, reinforcement, and applications. J. Mater. Sci. 56, 10812–10833 (2021).

林等. 关于硅气凝胶单体的近期进展综述:合成、增强及应用. 《材料科学杂志》56, 10812–10833 (2021).Welsch, T. et al. Comparison of different aerogel granules for use as aggregate in concrete. Gels 9, 406 (2023).

Welsch, T. 等. 不同气凝胶颗粒在混凝土中作为集料的比较。Gels 9, 406 (2023).Pan, Y. et al. A fast synthesis of silica aerogel powders-based on water glass via ambient drying. J. Sol Gel Sci. Technol. 82, 594–601 (2017).

Pan, Y. 等. 通过室温干燥制备基于水玻璃的气凝胶粉末的快速合成。溶胶-凝胶科学与技术 82, 594–601 (2017).Nocentini, K. et al. Hygro-thermal properties of silica aerogel blankets dried using microwave heating for building thermal insulation. Energy Build. 158, 14–22 (2018).

Nocentini, K. 等. 使用微波加热干燥的气凝胶毯的吸湿-热性能及其在建筑保温中的应用。能源建筑 158, 14–22 (2018).Tian, Y. et al. Ionic liquid-functionalized silica aerogel as coating for solid-phase microextraction. J. Chromatogr. A 1583, 48–54 (2019).

Jones, S. M. Aerogel: space exploration applications. J. Sol Gel Sci. Technol. 40, 351–317 (2006).

Iijima, T. et al. Aerogel Cherenkov counter for the BELLE detector. Nucl. Instrum. Methods Phys. Res. A 453, 321–325 (2000).

Li, L. et al. Thermal-responsive, super-strong, ultrathin firewalls for quenching thermal runaway in high-energy battery modules. Energy Storage Mater. 40, 329–336 (2021).

Erdem, C. et al. Toward aerogel based thermal superinsulation in buildings: a comprehensive review. Renew. Sust. Energy Rev. 34, 273–299 (2014).

Mendes, A. L. et al. Progress in silica aerogel-containing materials for buildings’ thermal insulation. Constr. Build. Mater. 286, 122815 (2021).

Lukas, H. et al. Fast and minimal-solvent production of superinsulating silica aerogelgranulate. Angew. Chem. Int. Ed. 56, 4753–4756 (2017).

Zhao, L. et al. Harnessing heat beyond 200 °C from unconcentrated sunlight with nonevacuated transparent aerogels. ACS Nano 13, 7508–7516 (2019).

Ji, X. et al. Elaborate size-tuning of silica aerogel building blocks enables laser-driven lighting. Adv. Mater. 34, 2107168 (2022).

Wang, L. et al. Structural characteristics and thermal conductivity of ambient pressure dried silica aerogels with one-step solvent exchange/surface modification. Mater. Chem. Phys. 113, 485–490 (2009).

Jansson, H. et al. Silicate species of water glass and insights for alkali-activated green cement. AIP Adv. 5, 67167 (2015).

Estella, J. et al. Effect of supercritical drying conditions in ethanol on the structural and textural properties of silica aerogels. J. Porous Mater. 15, 705–713 (2008).

Gurikov, P. et al. 110th anniversary: solvent exchange in the processing of biopolymer aerogels: current status and open questions. Ind. Eng. Chem. Res. 58, 18590–18600 (2019).

Schubert, U. et al. Aerogels–airy materials: chemistry, structure, and properties. Angew. Chem. Int. Ed. 37, 22–45 (1998).

Schubert, U. et al. Influence of supercritical drying fluid on structure and properties of organically modified silica aerogels. J. Non Crystal. Solids. 186, 37–43 (1995).

Du, Y. et al. Reaction-spun transparent silica aerogel fibers. ACS Nano 14, 11919–11928 (2020).

Rahul, D. M. et al. Creation of “Rose Petal” and “Lotus Leaf” effects on alumina by surface functionalization and metal-ion coordination. Angew. Chem. Int. Ed. 56, 16018–16022 (2017).

Almonte, L. et al. Rose petal effect: a subtle combination of nano-scale roughness and chemical variability. Nano Select 3, 977–989 (2022).

Zhang, J. et al. Durable superhydrophobic surfaces with self-generated wenzel sites for efficient fog collection. Small 20, 2312112 (2024).

Rao, A. P. et al. Modifying the surface energy and hydrophobicity of the low-density silica aerogels through the use of combinations of surface-modification agents. J. Mater. Sci. 45, 51–63 (2010).

Socrates, G. Infrared and Raman Characteristic Group Frequencies: Tables and Charts 3rd edn (Wiley, 2001).

Günzler, H. et al. IR spectroscopy: An Introduction 178–183 (Wiley-VCH, 2002).

Al-Oweini, R. et al. Synthesis and characterization by FTIR spectroscopy of silica aerogels prepared using several Si(OR)4 and R”Si(OR0’)3 precursors. J. Mol. Struct. 919, 140–145 (2009).

Jyoti, L. et al. Ambient pressure dried TEOS-based silica aerogels: good absorbents of organic liquids. J. Mater. Sci. 45, 503–510 (2010).

Malfait, W. J. et al. Surface chemistry of hydrophobic silica aerogels. Chem. Mater. 27, 6737–6745 (2015).

Wim, J. M. et al. Hydrophobization of silica aerogels: insights from quantitative solid-state NMR spectroscopy. J. Phys. Chem. C 118, 25545–25554 (2014).

Kimura, T. et al. Esterification of the silanol groups in the mesoporous silica derived from kanemite. J. Porous Mater. 5, 127–132 (1998).

Cao, C. et al. Robust fluorine-free superhydrophobic PDMS–ormosil@fabrics for highly effective self-cleaning and efficient oil–water separation. J. Mater. Chem. A 4, 12179–12187 (2016).

Pan, Y. et al. Surfaces with controllable super-wettability and applications for smart oil water separation. Chem. Eng. J. 378, 122178 (2019).

Amonette, J. E. et al. Functionalized silica aerogels for gas-phase purification, sensing, and catalysis: a review. Microporous Mesoporous Mater. 250, 100–119 (2017).

Abolghasemi Mahani, A. et al. Sol-gel derived flexible silica aerogel as selective adsorbent for water decontamination from crude oil. Mar. Pollut. Bull. 129, 438–447 (2018).

Jiang, H. et al. Liquid‐in‐aerogel porous composite allows efficient CO2 capture and CO2/N2 separation [J]. Small 19, 2302627 (2023).

Ren, J. et al. Transparent, robust, and machinable hybrid silica aerogel with a “rigid-flexible” combined structure for thermal insulation, oil/water separation, and self-cleaning. J. Colloid Interface Sci. 623, 1101–1110 (2022).

Mahadik, D. B. et al. Effect of concentration of trimethylchlorosilane (TMCS) and hexamethyldisilazane (HMDZ) silylating agents on surface free energy of silica aerogels. J. Colloid Interface Sci. 356, 298–302 (2011).

Nihei, T. et al. Dental applications for silane coupling agents. J. Oral Sci. 58, 151–155 (2016).

Gurav, J. L. et al. Effect of mixed catalysts system on TEOS-based silica aerogels dried at ambient pressure. Appl. Surf. Sci. 255, 3019–3027 (2008).

Zhang, J. et al. Membrane wettability manipulation via mixed dimensional heterostructured surface towards highly efficient oil-in-water emulsion separation [J]. J. Membr. Sci. 672, 121472 (2023).

Acknowledgments

We are grateful for the support from the National Natural Science Foundation of China (Project 52173052 to X.Z.; 52203021 to L.L.) and the Natural Science Foundation of Jiangsu Province (Project BK20220296 to L.L.).

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Chaobo Huang, Xudong Jia, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions